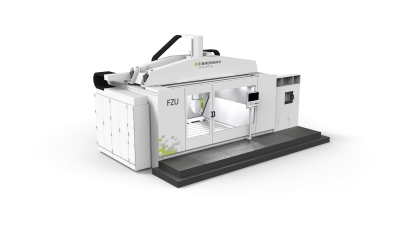

The demands for prototype, tool and mold making are increasing. Only those who can supply high-quality output, quickly and flexibly, can succeed against the powerful competition worldwide. Zimmermann is responding to this trend with the new FZU. This 5-axis gantry milling machine is not only compact but, thanks to its thermo-symmetrical design and accuracy, it also provides the ideal entry point to the Zimmermann machine line with maximum productivity. Plastics, casting resins such as Ureol and aluminum are particularly suitable for machining.

“This development will enable us to close the gap in the lower weight class,” states Frieder Gänzle, general manager and partner at Zimmermann in Germany. “The basic expectations, which prototype, tool and mold makers need to meet today, have not necessarily changed over the years, they have simply grown."

Customers in the automobile industry, he notes, especially expect components with almost perfect surface finishes and ever higher accuracies. Manufacturers introduce new models or variants to the market at ever shorter intervals. Whereas prototype, tool and mold makers could previously plan in the longer term, they must respond today to inquiries considerably faster.

“We cultivate a very special relationship with prototype, tool and mold makers,” says Gänzle. “Together, we have evolved consistently in recent years. We are very appreciative of our strong business in this sector.” Zimmermann is continuously exchanging technology information with its user base. In discussions, it has become clear that this sector requires powerful, compact machines with maximum productivity and open time.

And, importantly, Zimmermann must offer an attractive price/performance ratio, while meeting all these requirements. “We have evolved even further towards heavy-duty cutting, over the years,” reports Gänzle. “As a result, even the smallest machine in our portfolio, the FZ33 compact, has become more popular. We have continuously pushed it upwards from a technological point of view.”

Its focus is on aluminum cutting, but steel can also be machined. This enables Zimmermann to offer customers a very efficient, flexible and space-saving machine, while the corresponding design improvements have also had an effect on the price. “The requirement we were presented was for an entry-level model which rounds off our program at the lower price point,” explains Gänzle. The result is the FZU, a 5-axis gantry milling machine, which is optimized for weight and stability.

In contrast to the established FZ33 and other machines that Zimmermann offers, the company is taking a different path with the FZU. “We can narrow down the special features of this gantry machine to three main characteristics,” describes Gänzle. The first point: “We are following the trend towards modern manufacturing machines and designing them as space-saving, pre-assembled units.” This means Zimmermann assembles the machines in-house and can then transport them to the customer by truck or ship without having to dismantle them. Onsite, they are ready for use in a very short commissioning time; erection and start-up require minimum effort. For the customer, this means quickly available machines which can be installed without constructing foundations. “In the design, we have kept to the usual transport sizes. At the same time, the new FZU achieves a remarkable working range for its size,” explains Gänzle.

It is important to match the machine to the required dynamics. Adverse environmental conditions and long machine running times necessarily give rise to thermal expansion effects. In spite of the customers’ increased accuracy requirements, the machine must always achieve outstanding surface finishes. The Zimmermann engineers have therefore designed the FZU gantry machine to be thermo-symmetrical. This means that the milling spindle, guides and other accuracy-determining components are arranged so that their heating is either compensated or they can expand in uncritical directions. “This is the second important characteristic,” emphasizes Gänzle. The base frame consists of a steel welded construction which forms a continuous U-shape. The machine gantry’s centrally guided Z-slide has an octagonal section – and not a rectangular one like comparable machines – which makes it particularly stable. Thanks to its design, it therefore has impressive rigidity for its size. “With a weight of approximately 35 tons, a length of 3,500mm, width of 7,500mm and a height of just under 5,000 mm, we have been able to build a light and compact machine,” says Gänzle.

The third characteristic relates to the new VH10 milling head, which achieves an extremely high power density. “This new development has enabled us to reassess our portfolio,” reports Gänzle. This is because the VH10 head will replace the VH12, which is not a Zimmermann product. Alongside the VH20, VH30 and VH60, the VH10 is now the smallest head in the range. Users will also benefit from the fact that Zimmermann has suitable spare heads in stock and can supply them on request in the event of stoppages, for example, due to a crash. “We strive to respond quickly and provide the customer with optimum support,” emphasizes Gänzle.

Thanks to its slender design, the VH10 spindle head has only minimal interference contours. Compared to the VH12, it achieves almost double the clamping force. This is due to the fact that Zimmermann fits two side cheeks instead of one onto the unit. The VH10 is therefore considerably more stable in operation. In order to minimize throughput times, a powerful 34 kW spindle with a maximum speed of 24,000 rpm is used in the milling head as standard. “The FZU is therefore ideally suitable for the materials typically found in this business sector, such as Ureol, clay and aluminum. In the future, we will also use the new milling head in larger machines on which processers can produce one-to-one models – for example, on our FZ37,” says Gänzle.

To provide a high-quality machine at an attractive price, the designers at Zimmermann have turned their attention to remaining competitive with regard to price through increased component standardization, while at the same time addressing individual customer requirements. As with all machines produced, Zimmermann therefore also relies on a modular system with the FZU. Among other things, this approach enables different size variants and power levels to be produced. There are also numerous equipment options, which offer the customer maximum flexibility.

Zimmermann is therefore able to provide a very efficient solution with the new FZU. It is often the little things that give rise to success and customer satisfaction. “We place great importance on details – an aspect which cannot always be measured in the numbers,” explains Gänzle, who cites two examples: “For instance, the machining area is fully clad with stainless steel sheets in order to guarantee maximum resistance to abrasion. The FZU is also the first gantry milling machine to be equipped with our innovative, new NXP 24-inch multitouch controller, which is already used on our FZH horizontal machining center.” Another increasingly important topic is ergonomics. The door is divided asymmetrically to enable components to be easily fed to the machine. A small, easy-to-open door leads into the machining area, while the large door is used for loading. Operators therefore have a relatively large field of view, rapid access to the machining area and ample space for loading – ergonomic advantages which are not to be underestimated. Another detail is that a cabinet has been installed directly in front of the FZU. “This was the idea of one of our designers,” says Gänzle. “The tables, which users in the various plants position in front of the machines to place their accessories and service tools, caught his attention. With our solution, everything which is part of day-to-day operations can be safely stowed close at hand within the machine.” Added to this, there are extraction equipment and special chip management systems. “It is often the simple ideas which make the machine operator’s everyday tasks much easier,” sums up Gänzle.

To provide the best possible support to businesses, Zimmermann concentrates on high-quality and reliable service in close proximity to the customer. After all, this is exactly what characterizes a good relationship between supplier and user. “Customers expect high availability over the entire system lifecycle,” says Gänzle. “We provide comprehensive machine care.” This includes a customer hotline, by means of which users can reach a competent contact person, even outside of normal working hours, as well as a remote diagnosis system that allows a rapid response in an emergency. If mechanical components are defective or malfunction, the machine builder usually guarantees immediate shipment from its factory. In addition, the application engineers work together with the customer to optimize each individual combination of heads, spindles, tools and clamping equipment for the machines. Zimmermann therefore not only sells machines, but also complete solutions. Plans are in process for further upgrades to the stocking and service personnel staff in North America, as well. Zimmermann recently opened a new facility in Wixom, Michigan, near Detroit.

“We don’t want to be chasing trends; instead, we want to help shape the market,” says Gänzle. “Basically, we therefore aspire not to do the same things as our competitors.” To be technologically out in front, the machine builder never stands still with regards to machine development. The FZU is therefore being continuously optimized – without at the same time losing sight of the price/performance ratio. There appears to be substantial market interest in these machines, according to company research. The initial discussions with users were highly promising. “We are confident of meeting our customers’ requirements with this new development, both in Germany and internationally,” says Gänzle. The statement that the concept of the FZU could be transferred to the other machines in the program underlines how convinced he is of this new solution.

Contact Details

Related Glossary Terms

- concentrates

concentrates

Agents and additives that, when added to water, create a cutting fluid. See cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.