The newly-released version of WorkNC from Vero Software introduces two important new tools to the portfolio: a direct modelling CAD system and a Robot Module, making offline programming of robots easy, even for inexperienced users. Described as “the right CAD for CAM,” WorkNC Designer is a powerful new application focusing on the specific needs of machinist programmers, enabling users to create designs or modify existing geometry from third-party CAD systems.

WorkNC Designer is built on the Parasolid technology, bringing hybrid modelling and direct modelling capabilities that will revolutionize the way programmers prepare parts for manufacturing. WorkNC Brand Manager Miguel Johann says, “It’s not dependent on having a series of parameters that drive it, or a feature tree. It provides a very quick, dynamic editing and modelling environment, where users simply sketch, drag, hold, push or twist, to create and modify models.”

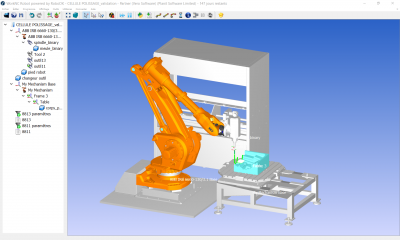

The second major item of new functionality is the Robot Module. “As robots are becoming more commonplace on the shop floor, there is an increasing need to provide offline programming for them. New simulation and singularity resolution tools in WorkNC 2018 R1 mean users can take full advantage of the enormous benefits robots bring to the manufacturing process,” Johann says. “For example, they free toolpaths from the limitations of milling, as the tool at the end of the robot’s arm can also be a grinder, a laser head, a welding nozzle, or indeed, any other tool that engineering creativity can think of.

“Robots also allow for the tool to be fixed, and the part to be moved around it, instead of the traditional method of a fixed component and moving tool. But robots are only as good as the software programming them, and this latest development in WorkNC 2018 R1 ensures that manufacturers can be at the cutting edge of robot technology.”

A number of new features have been incorporated into Waveform Roughing which improve efficiency and performance. These include support for new tools in trochoidal machining strategies, allowing for ramped lead-ins with high angles, typically between ten and 20 degrees.

Algorithms concerning the Z-step Auto Variable Strategy have been revised and improved, allowing for a smoother toolpath distribution on the part. “Also, with improvements to Tapping and Threading, it’s now possible to define Surface Selection in the Machining Zone section of the toolpath menu. Previously, surface management was fully automatic, and it wasn’t possible to ignore surfaces or add optional surfaces,” Johann says.

A major highlight is a change to the way part activation is managed, allowing for a rougher, lighter and simpler model to be used by Roughing Toolpaths, speeding up calculation times. In earlier versions of the software, one set of activation parameters was applicable for all types of toolpaths in a given work zone. Now, two sets can be defined by users, and Johann says setting specific values for roughing toolpaths creates a different mesh model, cutting calculation times by up to half.

The new Stock Initialization feature generates a stock model for just a specific area of a component, defined by selected surfaces. This is particularly useful when only certain areas of a part need to be repaired.

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.