Parts manufacturers perform boring to precisely enlarge and true a hole they have already drilled or cored. Sometimes boring prepares an ID for a subsequent operation, such as thread milling, slotting or grooving.

As in any metalcutting process for manufacturing precision parts, obstacles often arise and must be overcome to achieve customer specifications and profitability. The following case studies examine how several end users solved challenges by applying specific boring tools.

Down to Size

Doing the “little stuff” is Kayo Technologies’ forte, said Kevin Odom, owner of the Olive Branch, Miss., job shop. “I specialize in anything under 1 " in diameter and 3 " long.”

The jobs often come from other machine shops that are not able to produce those types of parts efficiently. Such was the case for a small bone screw ring made of Nitinol, a nickel-titanium shape-memory alloy that derives its name from its place of discovery: NIckel TItanium Naval Ordnance Laboratory.

“The company that was making them didn’t want to do them anymore,” Odom said. “They were doing them as a favor for the customer and weren’t making any money.”

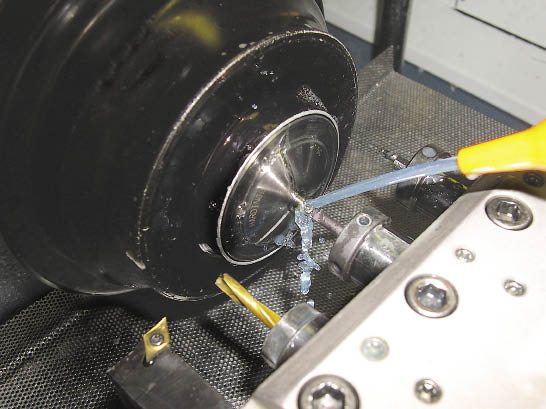

Courtesy of Kayo Technologies

Kayo Technologies applies Trim SC200 semisynthetic coolant when boring Nitinol with a 0.170 "-dia. Mini-Bore Trigon indexable-insert boring tool from Thinbit to produce bone screw rings (top) for the medical industry.

According to Odom, the part is made of a Nitinol alloy containing 45 percent nickel, which provides flexibility and high strength. After Kayo Technologies drills, bores, internal and external grooves and deburrs the 0.021 "-thick part, which has a 0.275 " OD and a 0.175 " ID, its customer wire EDMs a slot in the ring so it collapses in a groove in the bone plate and locks the screw in place.

Size tolerance is 0.001 ", but that’s only half the battle. “Appearance is as critical as size,” he said. “It’s a medical application so the finish requirement is 16 rms.”

The alloying elements that make the workpiece material suitable for its end use also make it difficult to machine. Odom never machined Nitinol before, so he needed appropriate cutting tools to do the job. The boring tool was the final piece in the tooling puzzle. He initially tried solid-carbide boring bars but was only able to bore about 50 parts before replacing the tool or resharpening it, and part runs total about 2,000. “I could regrind the solid-carbide one but it’s hard to hold size,” Odom said.

Nonetheless, he knows his way around a manual grinder. “When working on this little stuff, it’s hard to buy tools that really fit right, so I end up modifying tools all the time,” Odom said.

He felt an inserted tool would do a better job and found that Thinbit/Kaiser Tool Co. Inc., Ft. Wayne, Ind., offers one for boring a 0.170 "-dia. hole. After switching to the AlTiN-coated Mini-Bore Trigon inserts with three cutting edges from Thinbit, Odom was able to bore at least 400 to 500 holes per edge. “I could stretch it to do 2,000 parts with one insert,” Odom said, adding that he offset a tool a couple thousandths as an insert wore before indexing it and returning to the original size.

Odom noted that part of the increase in tool life was a result of switching coolants. The mineral oil in the previous coolant fell out of suspension and caused the machine to become sticky, preventing chips from washing into the chip pans and making it difficult to keep the machine clean. “It was plating out, as I call it,” he said. Odom switched to Trim SC200 semisynthetic coolant from Master Chemical Corp. and eliminated the problem while doubling tool life.

Compared to the uncoated solid-carbide tools, Odom was able to slightly reduce cycle time with the coated inserts, achieving a cutting speed of 70 sfm and a 0.001 ipr. “I could run it a little bit faster but with Nitinol you can’t run very fast anyway,” he said.

In addition to longer tool life, the slower rate of wear for the indexable-insert boring tools minimized workhardening and extended the life of subsequent tools. “When one tool wears, it workhardens the material so it takes out the next tool,” Odom said. After boring, he performed internal grooving to create an angle and external grooving and removed a burr from the part’s center via sanding.

The indexable-insert boring bars also are more economical than the solid-carbide tools, costing $10 an insert compared to $25 for the other. Each box of 10 inserts comes with a steel boring bar, but Odom found the boring bars to be fairly durable. “I went through about 30 inserts before the pocket finally wore out to where it wouldn’t hold an insert anymore.”

Double-Duty Head

Reducing cycle time was the objective for a boring application at Phoenix Products Co. Inc., but the Milwaukee-based manufacturer of lighting products also was able to use the same boring system with a different style of boring head to switch from interpolating a face groove to turning the face groove feature on the part, further increasing throughput.

The part is an aluminum housing for an explosion-proof industrial light, and Phoenix produces about 800 annually. Boring is performed to prepare the surface for thread milling, which is the final operation on the machine prior to manual deburring. The shop first applied the LCB1.5 large-diameter boring system from Criterion Machine Works, Costa Mesa, Calif., to produce the bore for the thread mill operation but based on a recommendation from Jim Anderson at Lars Anderson Co. Inc., Butler, Wis., a manufacturer’s representative for Criterion and Vardex USA, Janesville, Wis., Phoenix switched to a VersaTurn uncoated, upsharp, polished-top CGTC insert with a 20° positive top rake from Vardex.

“It’s an 8½ "-dia. bore that they were just taking an enormous amount of time to generate because most people aren’t going to think of spinning that big of a boring head on a 40-taper vertical machining center,” Anderson said, “much less get it through the toolchanger.”

Courtesy of Phoenix Products

A Criterion LCB1.5 large-diameter boring system with a different style of head attached and tooled with Vardex inserts grooves an aluminum housing for an explosion-proof light. Machinist Scott Vinz (top) optimized the part’s boring operation.

The boring tool was getting the job done to the required ±0.015 " tolerance but still too slowly for Scott Vinz, setup man, programmer and operator, when he began working at Phoenix. “The Criterion boring tools were being used but they weren’t being used to their full potential,” he said.

Vinz optimized the operation by upping the feed rate until the spindle load meter reached 100 percent and then backed off slightly. That achieved a feed of 15 ipm at a 1,000-rpm spindle speed. “I listened to the sound to make sure it sounded right, looked at the chips to make sure there was nothing odd and looked at the insert wear over two runs,” he said. “Seeing that it was right, I left it there.” Vinz noted that production went from a low of one piece per hour to a high of 14 pieces.

“Scott came in and helped push it up to where it should be,” Anderson said. “It probably took at least 90 percent of the cycle time out.”

Achieving that level of cycle-time reduction isn’t typically expected. “I was impressed with how much I could push it without the machine stalling and without the inserts breaking or wearing,” Vinz said. “I think I changed the inserts once and I’ve been here going on 2 years.”

“You don’t worry about the number of inserts you’re selling,” Anderson said. “It’s about taking care of the customer’s needs so they’re in business next year.”

The same Criterion LCB1.5 large-diameter boring system with a different style of head attached was again able to boost productivity by enabling Phoenix to use it for face grooving. Anderson explained that some Criterion heads accept various round-shank tools, allowing them to be applied for machining operations other than boring.

Previously, Phoenix used an 8½ " endmill to create an ⅛ "-wide O-ring slot. The process was time consuming and Anderson figured a Vardex face grooving tool in the Criterion head to create a twin-bar grooving system would do the task more efficiently. “It was just a natural to try that and it worked fabulously,” he said. “Customers need to be open-minded to look at new ways to solve existing applications, and Phoenix Products was.”

Tackling Tight Tolerances

Meeting tight-tolerance boring specifications is critical for every job shop, and possibly even more so for a young company trying to make its mark and generate repeat business. Sangat Precision Machining & Grinding Inc., Longmont, Colo., is one such job shop, having moved into a new 10,000-sq.-ft. facility about a year ago after operating out of the owner’s garage for a year. Since the move “we’ve just been buying machines, tooling up and getting ready,” said Eric Potter, senior machinist/programmer.

That tooling up involved buying boring tools to meet tolerances as tight as ±0.0002 " in difficult-to-machine materials. An experienced machinist, Potter is familiar with boring tools from various manufacturers and incorporated some of those in Sangat’s boring arsenal. Unfortunately, he experienced problems with tool backlash, adjustability and flexing. “Anything tighter than ±0.0005 " just seemed to be difficult,” he said.

Potter was also familiar with boring tools from BIG Kaiser Precision Tooling Inc., Elk Grove Village, Ill. “I know their accuracy, their ease of boring and the finishes you get out of their tooling,” he noted. With that in mind, he ordered one of the toolmaker’s Fullbore kits for boring holes from about 0.472 " to 6.0 ". The kit includes adjustable boring heads, holders, adapters for different tool lengths, inserts and a catalog to locate the appropriate part number for a specific application. “There were some long-reach jobs, so with BIG Kaiser you can get either high-speed steel or carbide extensions that have the insert on them,” Potter said.

The adjustability accuracy of the BIG Kaiser boring head also proved advantageous. “It goes right to the numbers,” Potter said. “If you need two more tenths, you dial it two tenths and away you bore.”

Sangat also desired modular tooling, and the BIG Kaiser heads accept adapters to be able to apply tools for other processes, such as shell milling and drilling. “If I want to change out boring heads I could have different sizes set up, and I wouldn’t need 10 different CAT 40 holders,” Potter said. “So you could yank the boring head out of a CAT 40 holder and it would repeat within millionths.”

Courtesy of Sangat Precision Machining & Grinding

Sangat Precision Machining & Grinding was able to achieve tight tolerances when boring after purchasing a boring kit with adjustable boring heads from BIG Kaiser.

That ability reduces setup time for a repeating aluminum part with a ±0.0003 " tolerance. Sangat set up a boring head for the job and keeps it on a shelf until the job repeats. At that point, Potter puts the head in a holder, loads it into the machine, touches off the tool length and bores to size.

In addition, unlike some boring tools that require additional setup to rotate the bar so the insert points in the right direction of the adjustment and then tightening the bar in place, Potter said a boring insert holder bolts onto the BIG Kaiser head and is always oriented in the right position. “We haven’t tracked setup-reduction time, but I know it has been reduced by the ease of setting up and switching over,” he noted.

Sangat enhances rigidity when boring by eliminating Z-axis movement through simultaneous toolholder taper and flange contact with the machine tool spindle using BIG Kaiser’s BIG-PLUS dual-contact spindle system and the corresponding option on its 5-axis Matsuura machine.

Potter noted that when he meets with Sangat’s BIG Kaiser representative, Rosie Mahoney of R. Mahoney & Co., Denver, he often says that boring makes many machinists nervous about having the proper setup to avoid producing scrap, but he doesn’t worry about that with BIG Kaiser boring tools. “I tell her she should use the phrase ‘BIG Kaiser makes boring fun.’ ” CTE

About the Author: Alan Richter is editor of Cutting Tool Engineering, having joined the publication in 2000. Contact him at (847) 714-0175 or [email protected].

Contributors

BIG Kaiser Precision Tooling Inc.

(888) TOOL-PRO

www.bigkaiser.com

Criterion Machine Works

(949) 631-5444

www.criterionmachine.com

Kayo Technologies

(662) 893-7569

Lars Anderson Co. Inc.

(262) 352-3400

Phoenix Products Co. Inc.

(414) 973-3420

www.phoenixproducts.com

Sangat Precision Machining & Grinding Inc.

(303) 702-1544

www.sangatprecision.com

Thinbit/Kaiser Tool Co. Inc.

(888) THINBIT

www.thinbit.com

Related Glossary Terms

- backlash

backlash

Reaction in dynamic motion systems where potential energy that was created while the object was in motion is released when the object stops. Release of this potential energy or inertia causes the device to quickly snap backward relative to the last direction of motion. Backlash can cause a system’s final resting position to be different from what was intended and from where the control system intended to stop the device.

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring bar

boring bar

Essentially a cantilever beam that holds one or more cutting tools in position during a boring operation. Can be held stationary and moved axially while the workpiece revolves around it, or revolved and moved axially while the workpiece is held stationary, or a combination of these actions. Installed on milling, drilling and boring machines, as well as lathes and machining centers.

- boring head

boring head

Single- or multiple-point precision tool used to bring an existing hole within dimensional tolerance. The head attaches to a standard toolholder and a mechanism permits fine adjustments to be made to the head within a diameter range.

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- modular tooling

modular tooling

1. Tooling system comprised of standardized tools and toolholders. 2. Devices that allow rapid mounting and replacement of tools. Commonly used with carousel toolchangers and other computerized machining operations. See toolchanger; toolholder.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- precision machining ( precision measurement)

precision machining ( precision measurement)

Machining and measuring to exacting standards. Four basic considerations are: dimensions, or geometrical characteristics such as lengths, angles and diameters of which the sizes are numerically specified; limits, or the maximum and minimum sizes permissible for a specified dimension; tolerances, or the total permissible variations in size; and allowances, or the prescribed differences in dimensions between mating parts.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- workhardening

workhardening

Tendency of all metals to become harder when they are machined or subjected to other stresses and strains. This trait is particularly pronounced in soft, low-carbon steel or alloys containing nickel and manganese—nonmagnetic stainless steel, high-manganese steel and the superalloys Inconel and Monel.