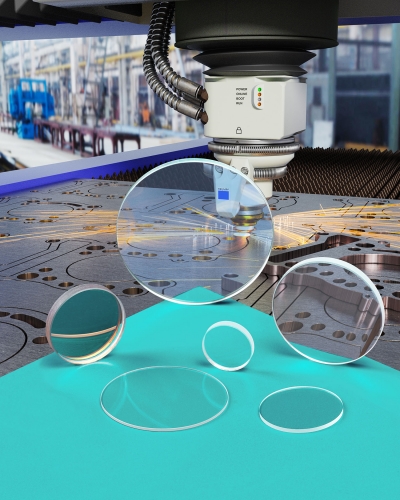

A line of sapphire cover glass windows that reduce focus shift and are suitable for use as debris shields on 1,064 nm cutting and welding lasers has been introduced by Laser Research Optics.

Laser Research Sapphire Fiber Laser Windows are suitable for use as debris shields on high power lasers from 4 kW up and have lower bulk absorption with about 30 times higher thermal conductivity than fused silica protect-tion glasses. Featuring Mohs 9 hardness, which is second only to diamond, they have A/R coatings on both sides to provide transmission of > 99.5% @ 1.06 microns with > 80% @ 650-670 nm.

Reducing focus shift and the deterioration of beam quality, Laser Research Sapphire Fiber Laser Windows can withstand steel splatter, flash, and debris better than fused silica which extends their service life and the required lens changes. Available in 0.5” and 2.0” sizes, they have a 10-5 scratch-dig finish and 1/4 wave transmitted wavefront.

Contact Details

Related Glossary Terms

- flash

flash

Thin web or film of metal on a casting that occurs at die partings and around air vents and movable cores. This excess metal is due to necessary working and operating clearances in a die. Flash also is the excess material squeezed out of the cavity as a compression mold closes or as pressure is applied to the cavity.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.