In the ever-evolving landscape of tramp oil contamination, the choice between belt skimmers and tube skimmers has sparked ongoing debates, with advocates on each side passionately championing the merits of their preferred technology. In this white paper, Tom Hobson of Abanaki explores the depths between belt skimmers and tube skimmers for effective oil removal.

Belt skimmer enthusiasts extol the virtues of space efficiency, while tube skimmer proponents emphasize the broader coverage these devices offer over sump, tank or pit surfaces.

Understanding the operating principle

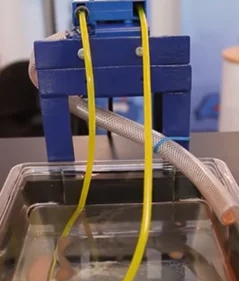

Despite the spirited discourse, both belt skimmers and tube skimmers share a common operating principle – breaking the surface tension of water to facilitate the adherence of oil to either the rotating belt or the floating tube.

Recognizing this commonality is essential, as it underscores the need to align your choice with the specific requirements of your application.

Key features and advantages of belt skimmers

Belt skimmers exhibit a range of features that contribute to their widespread use and

appeal.

1. Adaptability: One of the standout features of belt skimmers is their adaptability to various environments.

Whether deployed in calm waters, busy harbors, or industrial settings, these skimmers prove versatile and effective.

2. Floating Debris Management: In environments where floating debris is a concern, belt skimmers shine. Their design ensures efficient oil collection while preventing clogging caused by debris, making them ideal for diverse water conditions.

3. High Capacity: Belt skimmers boast impressive oil removal capacities, making them suitable for handling both small and large-scale spills. Their ability to process significant volumes of oil efficiently is a crucial advantage in emergency response scenarios.

Key features and advantages of tube skimmers

Tube skimmers, operating on a different principle, offer unique features that make them particularly effective in specific contexts.

1. Low Maintenance: Tube skimmers are celebrated for their simplicity and low maintenance requirements. This characteristic makes them a cost-effective and reliable choice for long-term deployment, minimizing operational disruptions.

2. Shallow Water Operation: The design of tube skimmers lends itself well to shallow water environments where other skimming methods may face limitations. This feature enhances their versatility in spill scenarios with varying water depths.

3. Variable Tube Sizes: Tube skimmers come in various tube sizes, providing adaptability to different spill scenarios. This flexibility ensures that these skimmers can effectively operate in diverse environments, addressing the specific challenges posed by varying spill conditions.

Decision-making considerations

Now, let's delve deeper into the practical considerations that should guide your decision-making process.

1. Oil Removal Rate: Evaluate the volume of oil you need to remove, measured in gallons per hour. Each skimmer model is specifically rated for its capacity to remove oil within defined time frames.

2. Tank Dimensions: Assess the dimensions of your tank or pit. Different skimmer sizes have varying capacities to pull in oil from different distances. Even if your oil volume is relatively low, selecting the appropriate skimmer size ensures effective coverage across extensive surface areas.

In the ongoing belt skimmer versus tube skimmer debate, the crux lies in aligning your choice with the practical needs of your application. By carefully scrutinizing factors such as oil removal rate and tank dimensions, you can tailor your selection to seamlessly address the unique challenges presented by your environmental context.

Informed decision-making remains the key to implementing efficient oil cleanup solutions that not only conserve space but also enhance functionality, ultimately contributing to a cleaner and more resilient environment.

Contact Details

Related Glossary Terms

- tramp oil

tramp oil

Oil that is present in a metalworking fluid mix that is not from the product concentrate. The usual sources are machine tool lubrication system leaks.