Heule Precision Tools will feature its BSF tooling for automated high-volume back spot facing applications in IMTS booth #431364.

The company says that the tools are ideal for counterbores up to 2.3 x diameter and ranging in size from 6.5mm to 20.5mm (0.256” to 0.807”).

BSF tooling is available with three activation methods to suit any machining environment, including:

- CNC machines with through-spindle coolant with at least 300 psi,

- CNC machines with through-spindle air with at least 60 psi, and

- a new manual version with easy collar locking /unlocking mechanism.

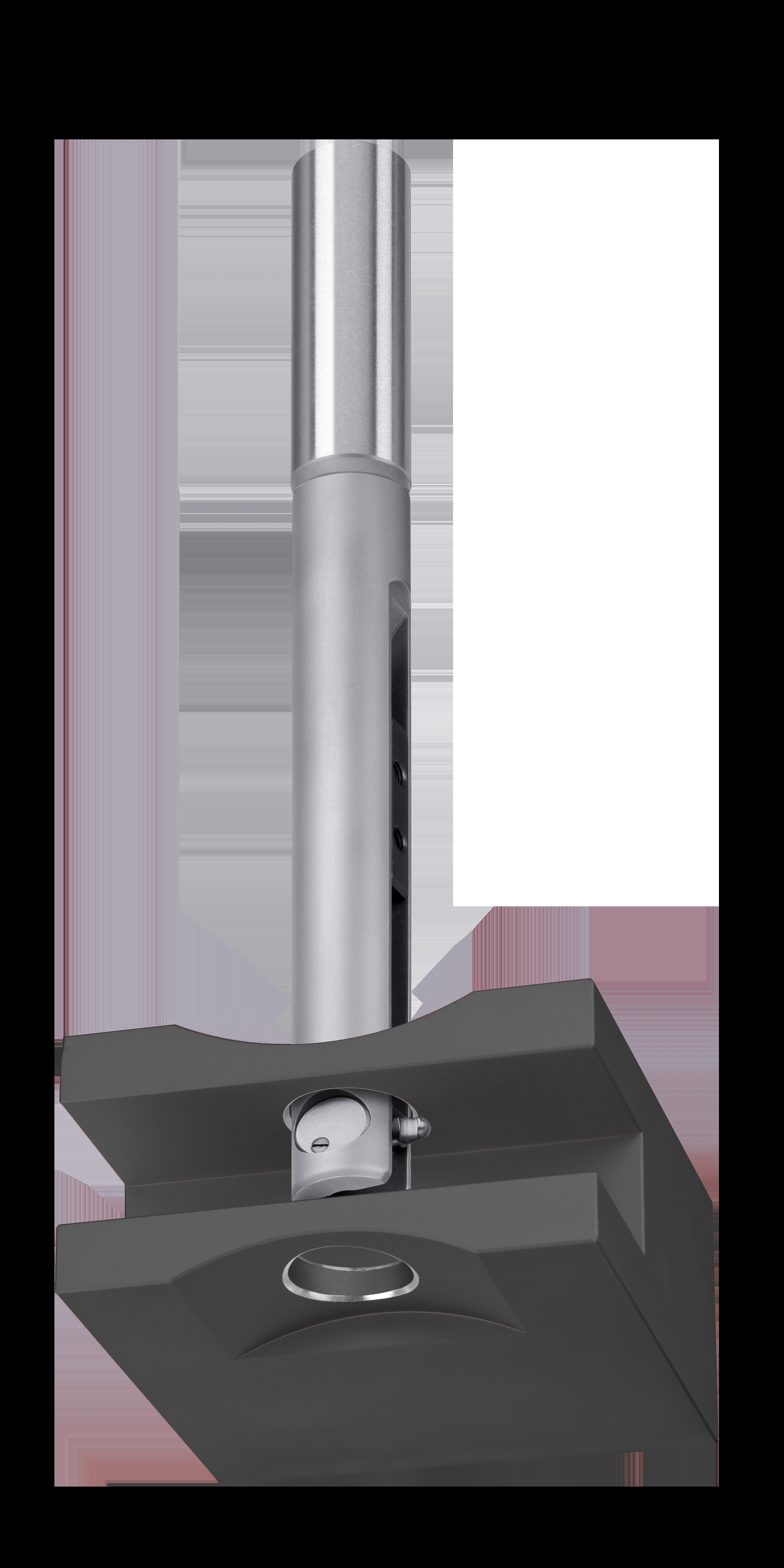

BSF tooling is designed for CNC machining and functions without an anti-rotation device, change of spindle direction, or contact mechanism, allowing components to be spot faced in the same direction as the bore is drilled. This saves the time and cost of turning the work piece, while allowing the spot-facing of difficult to reach areas like casting flanges, and bolt head faces.

BSF tooling is designed for CNC machining and functions without an anti-rotation device, change of spindle direction, or contact mechanism, allowing components to be spot faced in the same direction as the bore is drilled. This saves the time and cost of turning the work piece, while allowing the spot-facing of difficult to reach areas like casting flanges, and bolt head faces.

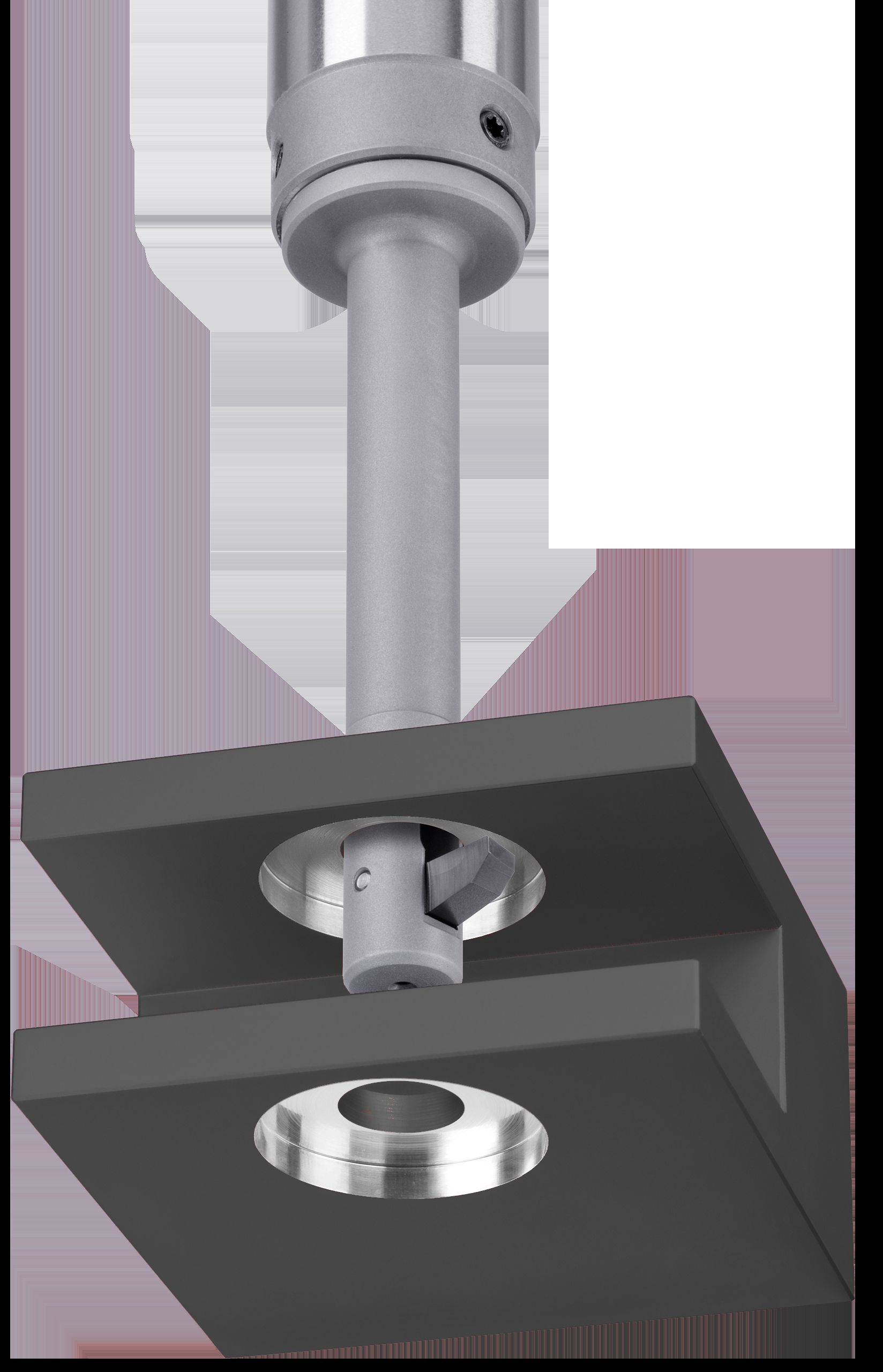

The swing mechanism combined with one of the three activation methods yields optimal cutting performance, resulting in consistent spot facing and fewer scrapped parts.

BSF tooling is stocked in the Cincinnati area warehouse for immediate shipment. They are ideal for gear housings, yokes, engine casings, and other parts in a wide range of materials, the company says.

The blade expands using centrifugal force when activating the spindle, and retracts from coolant pressure, air pressure, or manually, which moves a piston to depress a pin that retracts the closed blade into the blade housing. The tool works both vertically and horizontally, with replaceable carbide-coated blades for extended tool life.

Designed for optimal cutting performance, chip removal, and reliability, the BSF coolant-through tool and blade feature special coolant pipes and chip-guiding geometries that continuously flush the blade window and the blade itself with coolant. This keeps the work area clean and allows for optimal chip removal. All tool components and blades are easy to replace, the company adds.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.