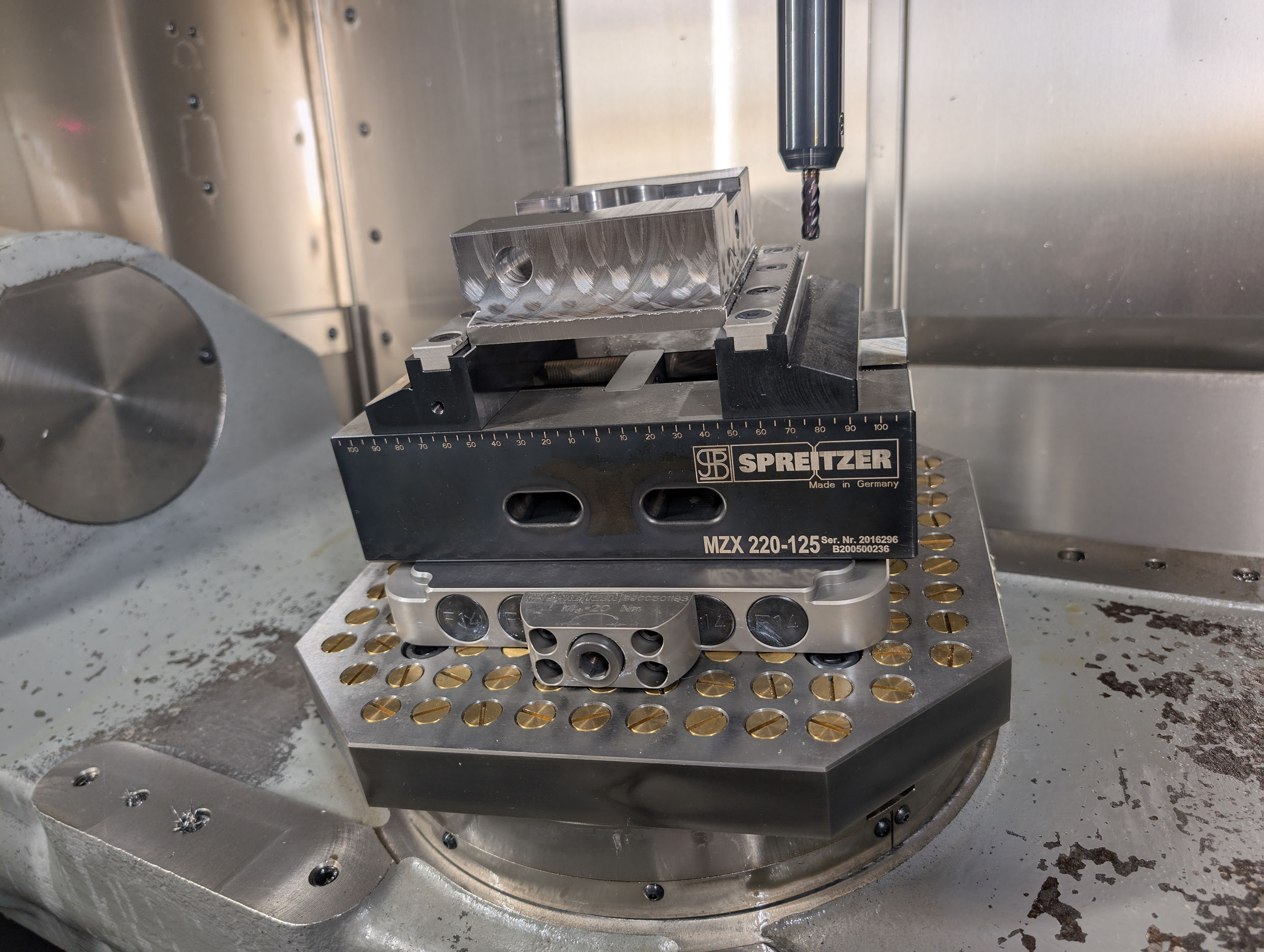

Spreitzer GmbH & Co. KG, a global supplier of mechanical, pneumatic, hydraulic, and electromechanical centric vises, has developed its new mechanical centric vise MZX that the company says is designed to meet the highest demands in workpiece clamping.

As a pioneer and originator in the field of centric vises since the launch of the MZS series in 1983, Spreitzer once again sets new benchmarks in mechanical clamping technology with the MZX. According to the company, the new model is a "consistent further development of a proven principle, tailored to the requirements of modern manufacturing environments and zero-point clamping systems."

Maximum clamping force

The MZX features a powerful spindle, zero-backlash spindle bearing, and stable jaw guidance. The result is uniform, process-reliable clamping with a repeat accuracy of 0.01 mm. The open construction allows for efficient chip evacuation, ensuring smooth machining processes.

The MZX is suitable for both raw and finished part clamping. Its interchangeable jaw variants with integrated grip inserts, clamping rails, as well as grip jaws following the Spreitzer system, or versions compatible with pre-stamping systems from LANG. A wide range of sizes, prepared for zero-point systems with grid dimensions of 52 × 52 mm or 96 × 96 mm, ensures maximum compatibility with systems from various manufacturers.

MDX: The sister model for double efficiency

In addition to the MZX series, Spreitzer offers the mechanical double centric vise MDX, which enables the simultaneous clamping of two workpieces against a fixed stop. The special spindle design allows workpieces with length variations up to 2 mm to be clamped securely.

This makes the MDX ideal for use in automated production lines, palletizing systems, and serial manufacturing. Like the MZX, the MDX also uses interchangeable jaws, allowing for flexible clamping of both raw and finished parts.

Automation-ready design

Both the MZX and MDX are fully compatible with modern automation and zero-point clamping systems. Upon request, Spreitzer provides customized gripper grooves, enabling automated vise exchange. A broad range of compatible interface patterns and mounting systems (e.g. LANG, SCHUNK, STARK, ZeroClamp, and others) emphasizes the high system openness of the series.

With the new MZX and its twin model MDX, Spreitzer once again demonstrates its innovative strength and leadership in the field of centric vises. The combination of mechanical robustness, application versatility, and process reliability makes this new series the first choice for modern, automated production.