AdvantEdge FEM 5.8

AdvantEdge FEM 5.8

Machining modeling software developer Third Wave Systems' AdvantEdge FEM 5.8 is a material physics-based software solution for optimizing metal cutting, providing detailed information about chip formation, temperatures, stresses, and forces for machining processes.

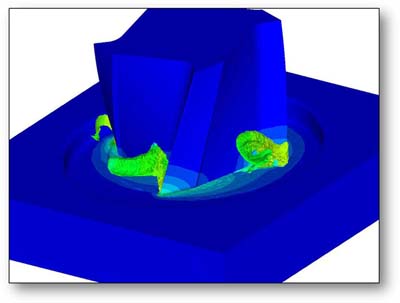

Machining modeling software developer Third Wave Systems' AdvantEdge FEM 5.8 is a material physics-based software solution for optimizing metal cutting, providing detailed information about chip formation, temperatures, stresses, and forces for machining processes. The technology provides users with data not available from trial-and-error tests, making it an invaluable tool for cutting tool design and analysis.

Capitalizing on performance improvements made in 2010 and early 2011, AdvantEdge FEM version 5.8 includes several new modeling capabilities that have been under development for years. These capabilities, coupled with ongoing performance speedups and computational enhancements, provide cutting tool manufacturers and process engineers with a more comprehensive resource for realizing optimal tool performance and getting new products to market faster.

Among AdvantEdge FEM 5.8's new and enhanced capabilities are:

Orbital drilling modeling in 3D, the newest machining process modeled by the software. AdvantEdge FEM 3D is also capable of modeling milling, turning, drilling, boring, tapping, and grooving.

Coolant pressure modeling in 2D, enabling users to predict the influence various coolant strategies will have on chip formation.

3D user-defined yield surface material modeling capabilities, enabling users to easily define their own materials, including Johnson-Cook material models.

Frictional and contact model algorithm enhancements, providing improved accuracy in 3D results.