Bandsawing Calculator

Bandsawing Calculator

Simonds International has introduced SnapShot, the latest addition to its Cutting Intelligence arsenal, a suite of analysis tools designed to help manufacturers identify savings opportunities.

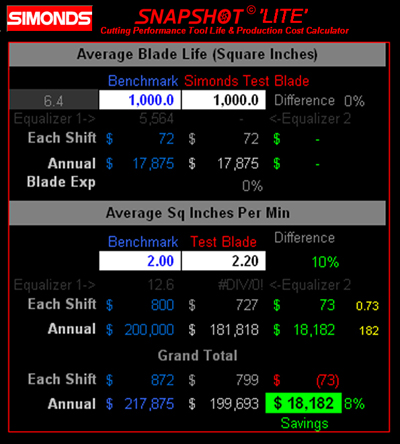

Simonds International has introduced SnapShot, the latest addition to its Cutting Intelligence arsenal, a suite of analysis tools designed to help manufacturers identify savings opportunities. The SnapShot Bandsawing Calculator is a data-driven Microsoft Excel tool that identifies and measures the impact of improved productivity and performance on day-to-day bandsawing operations and their effect on profitability.

The SnapShot calculator guides manufacturers through the individual cost components of their sawing operation, including:

Cycle/Cut Times

Blade Life (in square inches)

Crooked Cuts/Week Pinch (Frequency per Week)

Cut (Surface) Finish/Hours Per Shift

Noise Cost/Year

Operator Training/Year

Machine Repair Service/Year

Other Annual Value

For those categories with indirect value, SnapShot allows customers to measure their value on "soft" costs. The tool ultimately identifies opportunities for significant time and cost savings.

"In sawing, even small changes can yield significant time and cost savings. Taking a closer look at the scope of a bandsawing operation can uncover some surprising results," said Dale Petts, Global Product Manager, Metal Products, at Simonds International. "Some of our customers are seeing six-figure annual savings after implementing opportunities that were identified via a SnapShot analysis of their sawing operation."