Contact Details

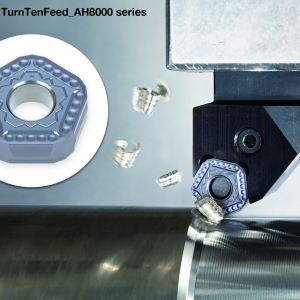

Tungaloy has expanded its BoreMeister exchangeable head deep boring tool system by adding three sizes of anti-vibration bars integrated with size C6 PSC machine-side connection, as well as reducer sleeves in six sizes for clamping stability and accuracy.

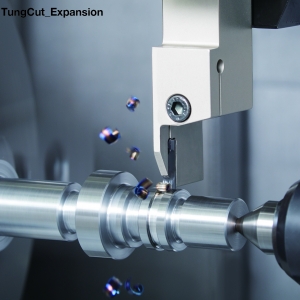

The new anti-vibration boring bars with C6 PCS machine side connection are suitable for up to 9xD boring depths, allowing direct assembly on the machine spindle or turret without the need for adapters. The boring bars can also minimize chatter as an integrated vibration damper suppresses unwanted vibrations during machining.

Also added are reducer sleeves with splits designed for holding anti-vibration boring bars in sizes 7xD and 10xD. When coupled with a boring bar and installed in the clamping unit or on the turret, these sleeves collapse to achieve maximum contact area, ensuring a full grip on the boring bar shank for much higher clamping stability than conventional direct screw-clamp method.

The BoreMeister system

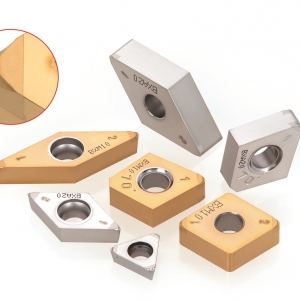

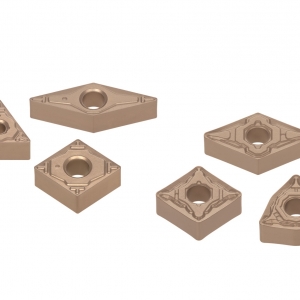

BoreMeister system is supplemented with a variety of exchangeable heads and shanks for internal turning, threading, and grooving. The system ensures vibration-free boring operations in a long overhang setup of up to 10xD through a dampener inside the tool body. The serrated interface of the head shank connections provides the insert cutting point with high repeatability and accuracy.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring bar

boring bar

Essentially a cantilever beam that holds one or more cutting tools in position during a boring operation. Can be held stationary and moved axially while the workpiece revolves around it, or revolved and moved axially while the workpiece is held stationary, or a combination of these actions. Installed on milling, drilling and boring machines, as well as lathes and machining centers.

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS