Contact Details

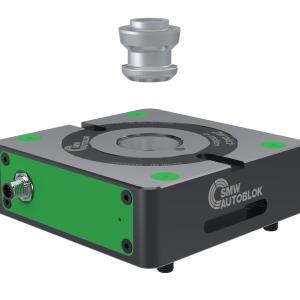

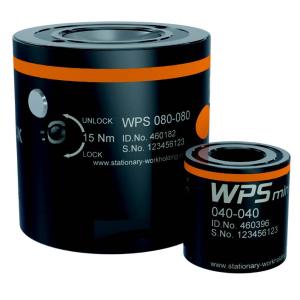

SMW Autoblok, a world leader in the design and manufacture of rotational chucks, stationary workholding, tooling and custom engineered solutions for the machine tool industry, introduces the innovative CCS chuck changing system.

Providing excellent repeatability that is guaranteed within 10 microns, the CCS can be installed in under three minutes on new or existing lathes that saves time and increases operator productivity. A standard adapter system provides automatic push off and easy mounting to all types of traditional or custom workholding including 2-jaw chucks, 3-jaw chucks, collet chucks, mandrels, and manual fixtures, among others.

With a simple turn of a key, quickly connect workholding devices to the machine spindle and draw tube of the actuating cylinder. This guarantees operator safety in addition to minimizing machine downtime. A large through hole and a visual safety control of the locking status completes the versatility of the CCS chuck switching system.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

PRODUCTS

PRODUCTS