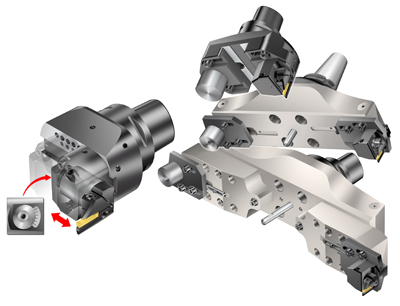

CoreBore 825 SL Face Grooving Heads

CoreBore 825 SL Face Grooving Heads

Machine shops seeking competitive gain in face grooving applications should look no further than the new CoroBore 825 SL face grooving heads from Sandvik Coromant.

Machine shops seeking competitive gain in face grooving applications should look no further than the new CoroBore 825 SL face grooving heads from Sandvik Coromant. This rotating axial face grooving tool offers a productive alternative to milling grooves for those operating in, or serving sectors such as pumps and valves, hydraulics and the pulp and paper industry.

The solution uses a standard SL32 blade and CoroCut 1-2 inserts, but features through-coolant capability for enhanced chip control. This, in combination with high levels of rigidity, allows increased cutting data.

Chip evacuation is a concern in any metalcutting operation but is critical when grooving because chips are more prone to being trapped inside a groove and being recut. As a result, through-tool coolant delivered right to the cutting edge can be enormously beneficial.

CoroBore 825 SL face grooving heads offer radial fine adjustment for presetting purposes and are available for diameters from 47 to 1275mm. For smaller diameters (1.85 to 5.91"/47-150mm) C6 and C8 adaptors are available, while for larger diameters (greater than 5.91"/150mm) a dedicated face grooving head with CoroBore XL can be deployed.

The first choice insert geometries are -CM for small nose radii (less than 0.0078"/0.2mm) or -TF for larger nose radii (greater than 0.0078"/0.2mm), the recommended starting value for feed rate is 0.006 in/rev (0.15mm/rev). However, if grooves with smaller width tolerances are required -GF geometry is the preferred choice. Here, a feed rate of around 0.004 in /rev (0.10mm/rev) is the recommended starting value.

For applications involving other shapes, such as V-grooves for example, Tailor Made insert solutions are available.