Contact Details

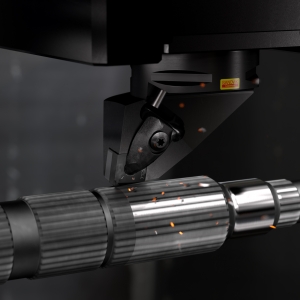

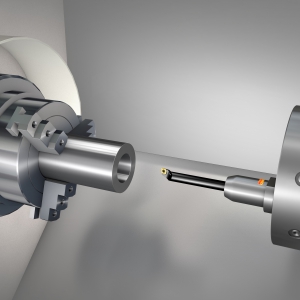

Sandvik Coromant is introducing its CoroBore BC (Boring Combination) range of products, comprised of TailorMade tools for high-volume applications. Using CoroBore BC, it is possible to perform different operations such as semifinishing and chamfering with a single tool. Manufacturers set to benefit include those serving the automotive, general engineering and construction equipment sectors.

CoroBore BC offers a quick and easy alternative when standard tools do not meet specific requirements, but the cost and delivery time of a specially engineered solution are prohibitive. The process is fast, as Sandvik Coromant personnel utilize an online program that automatically creates the tool and provides price and delivery information.

“The productivity advantages offered by CoroBore BC tools are based on eliminating unnecessary tool changes and reducing cycle times,” says Jenny Nilsson, global product manager, Sandvik Coromant. “Among the many strengths of the new solution is the capability to offer these benefits on much shorter notice, thanks to an automated design and quoting process. The Sandvik Coromant representative simply goes through the required operations and parameters with the customer, and enters the parameters via a web-based design interface. Once this is complete, the system instantly produces the tool design and quote.”

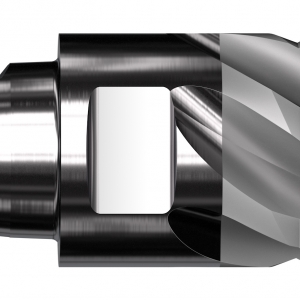

Thanks to the various CoroBore BC options offered, a range of multiple-step boring applications can be performed. Indeed, customers can choose from up to four machining operations in a single tool (a maximum of two cutting edges per operation). Cutting diameters range from 20 to 200 mm (0.787 to 7.874 inch), while tool length can be up to 400 mm (15.75 inch), depending on the coupling size. Coupling options include Coromant Capto, HSK Form A and ISO 9766, as well as ISO/Mas-BT/Cat-V tapers. The range of supported coupling models and sizes usually enables direct integration with the machine interface, thus eliminating the need to use a separate basic holder.

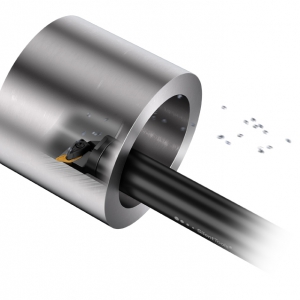

CoroBore BC insert-carrier solutions use CoroBore cartridges. Compared to fixed insert pockets, this configuration enables easy and efficient cartridge changes. As standard stocked items, both the insert and insert carrier are easily replaceable on short notice.

The cartridges come in three configurations: radially and axially adjustable; axially adjustable only; and non-adjustable. All cartridge options are equipped with high-precision coolant nozzles capable of using coolant pressures up to 80 bar (1,160 psi), a unique benefit in tailored multiple-step boring tools.

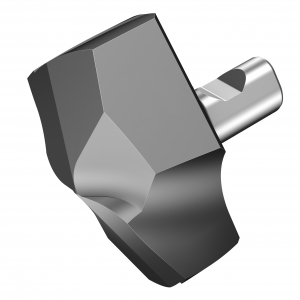

In addition to standard ISO inserts, CoroBore BC boring tools can be fitted with proprietary CoroBore 111 inserts, which come with optimized grade options for medium and rough boring. All in all, the Sandvik Coromant insert program offers productive geometries and grades for all types of materials and boring operations.

Ultimately, the unique benefits of CoroBore BC present machine shops with an option to receive a tool with a reduced lead time compared to an engineered tool – and at a more attractive price point.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- chamfering

chamfering

Machining a bevel on a workpiece or tool; improves a tool’s entrance into the cut.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

PRODUCTS

PRODUCTS