Contact Details

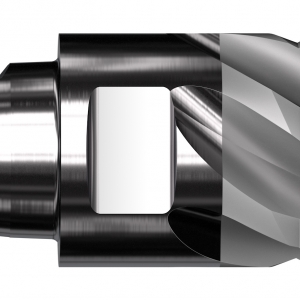

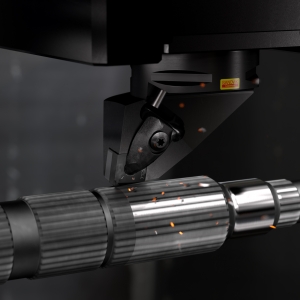

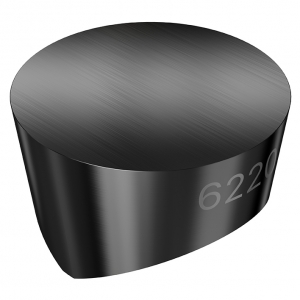

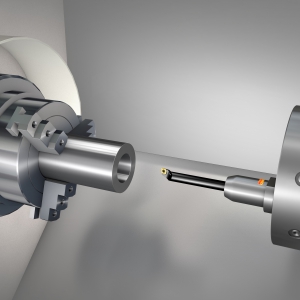

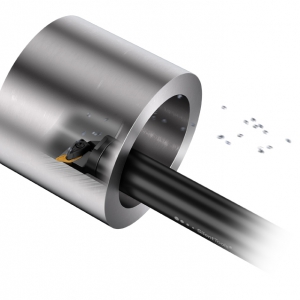

When material savings are a requirement due to machining expensive materials, large batch productions or both, it is essential to use the thinnest insert width possible. CoroCut QD dedicated parting off and deep grooving tools from Sandvik Coromant Co. are available in small insert widths with internal high-pressure coolant to help customers realize production efficiency.

Considered a “hidden machining cost,” component material waste is an often-overlooked production expense. Wider insert blades cut more material than necessary during each parting off operation with the excess material ending up in the chip bin. Using a thinner insert blade not only wastes less material but also allows for more parts per bar when parting off using a bar feeder. Realizing this material savings is especially important for those who machine components made of expensive materials, such as heat-resistant super alloys like Inconel, titanium and cobalt chrome. When working with these high-priced materials in higher volumes, using a thicker insert blade can be costly.

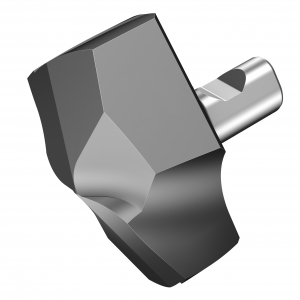

For smaller insert widths, insert handling is easily accomplished with the use of the insert cam key. Accompanied with each CoroCut QD, the cam key allows the user to leave the finger of the blade in the open position allowing for use of both hands for insert positioning. With the turn of the cam key, the new insert clamp design offers improved rigidity for process security. CoroCut QD toolholders are made using the same improved tool steel as the larger width CoroCut QD, resulting in 12 percent higher tensile strength.

According to Staffan Lundström, Parting and Grooving Product Specialist at Sandvik Coromant, “As the only product currently on the market that offers over and under coolant in a tool this thin, the CoroCut QD inserts in 0.04 inch, 0.05 inch and 0.06 inch work well for deeper cuts and larger diameters and for all materials, especially HRSAs.” Parting and Grooving Specialist Scott Lewis adds, “Shops that solely focus on tool costs can be missing the big picture. When a tool costs you more in material waste over time, especially expensive materials, the overall cost to machine a component can be much higher than expected.”

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- tensile strength

tensile strength

In tensile testing, the ratio of maximum load to original cross-sectional area. Also called ultimate strength. Compare with yield strength.

PRODUCTS

PRODUCTS