Contact Details

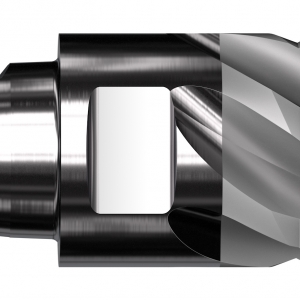

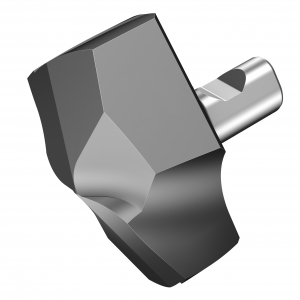

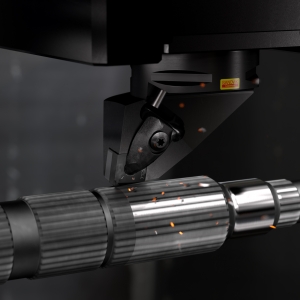

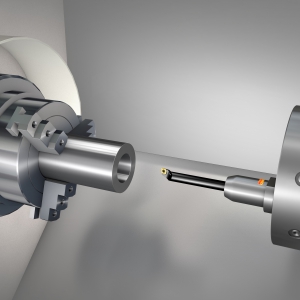

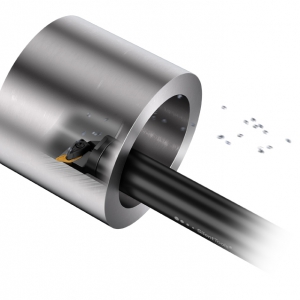

Sandvik Coromant has introduced the CoroDrill 460-XM. The new drill is a multi-application, high-performance drill that can be used across a wide range of materials. This drill provides high capacity utilization, flexibility and versatility. With one drill for all materials, stock holding can be reduced and greater machine flexibility is offered leading to reduced set-up time.

The CoroDrill 460-XM is made from micro-grained carbide for an excellent combination of hardness and toughness, resulting in high wear resistance and longer tool life, the company reports. The coating has a special finishing treatment to reduce coefficient of friction. The strong web design provides excellent cross-sectional strength that, combined with increased flute volume, enhances chip evacuation. The point angle of 140 degrees is ideally suited for multi-application drilling, with good centering capabilities and low thrust force design.

The drill comes in a standard diameter range of 3 to 20mm (0.118 inch to 0.787 inch) in drill lengths; 2 to 5 times drill diameter (DIN 6537 K and DIN 6537 L). Achievable hole tolerance: IT8 to IT9 and is available with internal and external coolant.

Related Glossary Terms

- centering

centering

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- point angle

point angle

Included angle at the point of a twist drill or similar tool; for general-purpose tools, the point angle is typically 118°.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

PRODUCTS

PRODUCTS