Contact Details

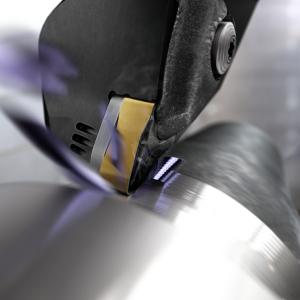

Sandvik Coromant has launched a new, light cutting insert for its innovative CoroMill 170 precision gear milling cutter. The -PL geometry flank insert reduces cutting forces, making it the best option for smaller gear milling machines, giving users the option to reduce power consumption or run for faster and longer.

The insert features a positive chip breaker that minimizes unwanted cutting forces and vibration. This helps produce less heat generation in the cutting zone and prolong insert life. In tests, the new -PL geometry shows 20 percent lower power requirement when the maximum chip thickness is less than 0.004 inch.

Taking advantage of Sandvik Coromant's grade GC1030, the technical features of the new insert support greater cutting stability and in turn allow higher cutting speeds. Working in the steel application area, typical operations include rough milling of internal and external gears, along with the machining of large gear wheels in the 12-22 module range. Sandvik Coromant recommends a lower feed than used for existing CoroMill 170 insert geometries such as -PM (medium) and -PH (heavy).

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

PRODUCTS

PRODUCTS