CoroMill MF80

CoroMill MF80

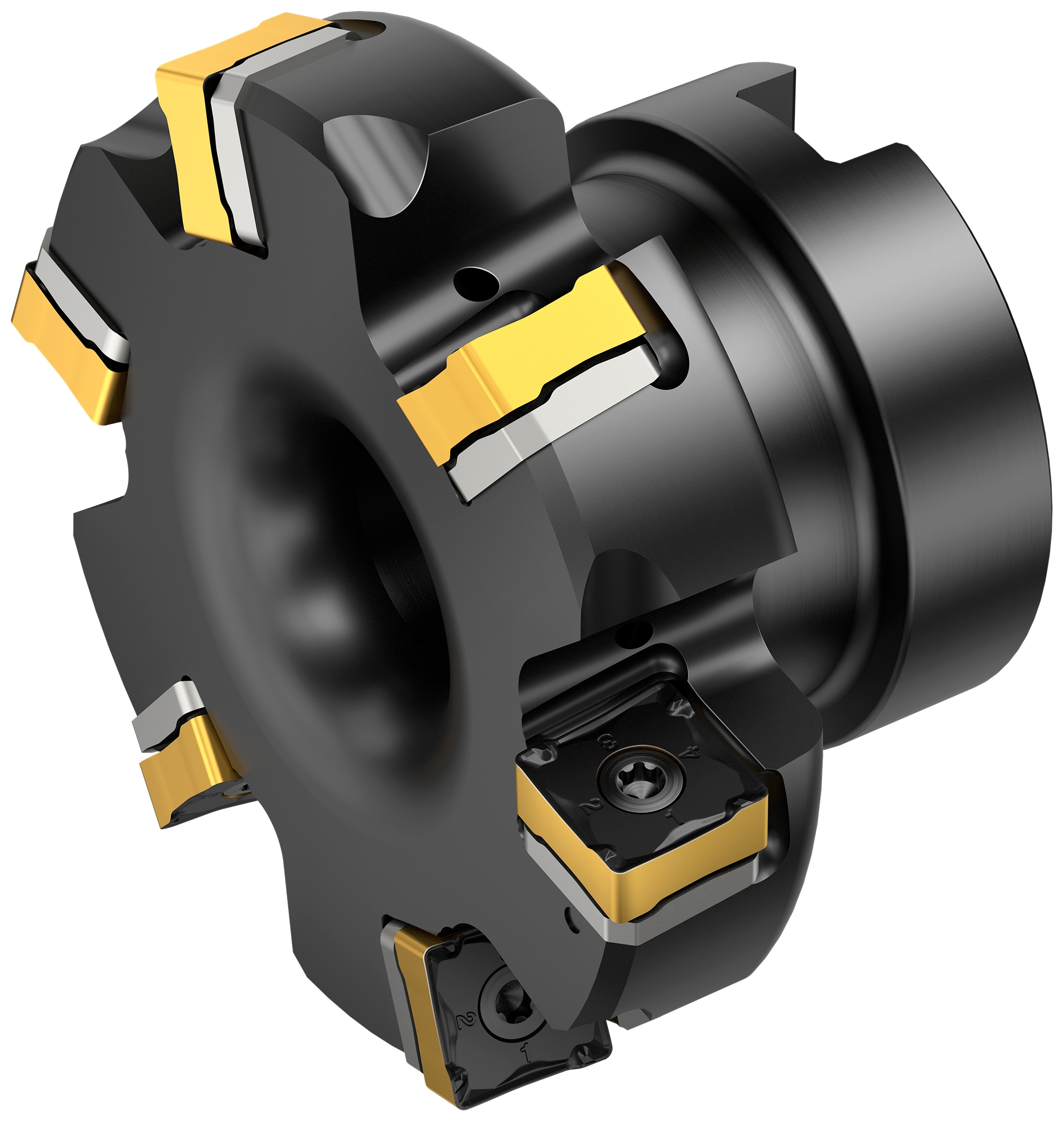

Based on a technology platform similar to the existing CoroMill® 345, this new milling concept offers a 40 percent lighter cutter body with shim protection and a high number of inserts for secure and stable machining, even in vibration-prone overhang applications. The 89.5-degree approach angle enables the multi-edge cutter to work close to the fixture, which not only greatly improves machine utilization, but also ensures a longer tool life with less scrap.

Global metal-cutting leader Sandvik Coromant is expanding its milling offering with the new CoroMill® MF80 for automotive milling applications in ISO K and ISO P materials in close to 90-degree operations with fixture constraints.

Based on a technology platform similar to the existing CoroMill® 345, this new milling concept offers a 40 percent lighter cutter body with shim protection and a high number of inserts for secure and stable machining, even in vibration-prone overhang applications. The 89.5-degree approach angle enables the multi-edge cutter to work close to the fixture, which not only greatly improves machine utilization, but also ensures a longer tool life with less scrap.

The inserts have eight cutting edges, chip protection and optimized micro geometry for better security and chip evacuation, as well as a wiper edge for a superior surface finish. The cutting edge is inclined for smooth cutting action and low cutting forces, making it ideal for thin-walled components and machine setups with limited stability.

In a roughing shoulder milling performance test with a competing brand, the CoroMill® MF80 showed a remarkable 67 percent increase in tool life, which, in turn, boosted overall productivity by 60 percent. After 40 minutes of machining, the comparison ended with 15 freshly machined components for Sandvik Coromant and 9 for the competitor. The shim protection and high number of insert edges effectively lowered cost per part in this roughing application.