Contact Details

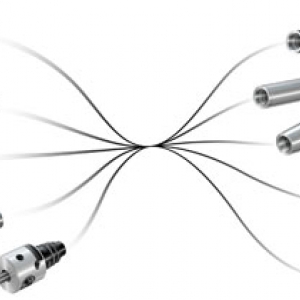

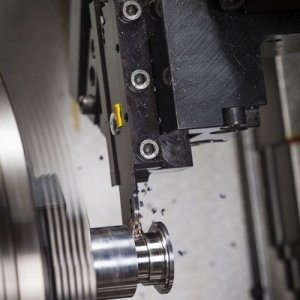

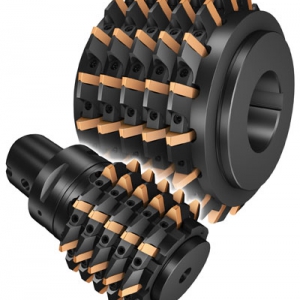

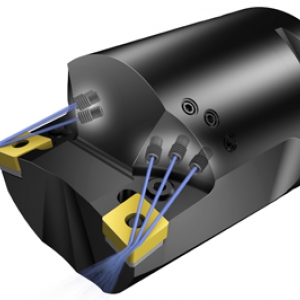

The new CoroMill 316 generation of exchangeable-head milling cutters from Sandvik Coromant further expands the company’s established solid, round tools portfolio by bringing higher levels of versatility and productivity to machining operations in ISO P (steel) and ISO M (stainless steel) materials. Further benefits include high reliability in almost all applications along with enhanced tool life and a silent machining process.

CoroMill 316 is suitable for all general milling operations, including high-feed facemilling, slot milling, helical interpolation, shoulder milling, profile milling and chamfer milling. The exchangeable heads allow users to easily and accurately switch between various operations, providing end mills with optimized radius variation, teeth frequency, geometry and grade. Beyond steel and stainless steel, the tools can also be used successfully in ISO K (cast iron) and ISO S (heat-resistant superalloys) materials.

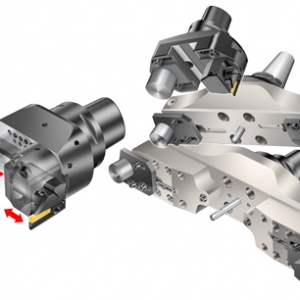

“The latest generation of CoroMill 316 adds longer cutting length to its list of attributes, delivering even greater flexibility for machine shops,” says Tiziana Pro, Product Manager Solid End Mills at Sandvik Coromant. “Specific operations to benefit include those that demand higher axial depth, up to 1.2 x DC, as well as operations where high stability and vibration suppression are required. In particular, the combination of the modular Coromant EH system and CoroMill 316 provides a number of solutions for all types of machines and user challenges.”

Manufacturers can choose Coromant EH as a rotating modular interface for applications up to 32 mm (1.256 inches) in diameter. Integrated machine adapters with EH coupling are recommended for small interfaces where gauge line and swing diameter are critical (BT30, SK40, HSK40/50/63, ER, DTH), as well as different shank types in long overhang applications up to 35 mm (1.38 inches) in diameter.

Related Glossary Terms

- facemilling

facemilling

Form of milling that produces a flat surface generally at right angles to the rotating axis of a cutter having teeth or inserts both on its periphery and on its end face.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS