Exchangeable-Head System

Exchangeable-Head System

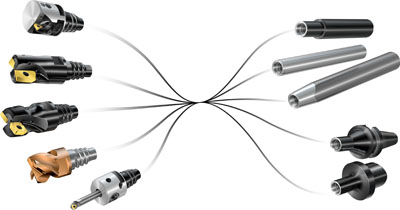

Sandvik Coromant's exchangeable-head (EH) system includes a wide assortment of solid carbide heads, indexable milling cutters, boring heads, integrated machine adaptors and different shanks.

Sandvik Coromant's exchangeable-head (EH) system includes a wide assortment of solid carbide heads, indexable milling cutters, boring heads, integrated machine adaptors and different shanks.

The exchangeable head coupling is based on a self-centering screw thread for secure mounting and maximum strength and security. The coupling has a physical stop which makes it easy to feel when the head is correctly tightened and helps to not overstress the clamping. The conical portion is shaped to provide best run-out. Pre-loaded taper and flange contacts provide an optimized modular connection with extreme rigidity and strength.

These new extensions meet the requirements for long reac in large machining centres in the diameter range of 0.394" to 1.26 inch (10 to 32mm) for milling and 0.039" to 1.42 inch (1 to 36mm) for boring.