Contact Details

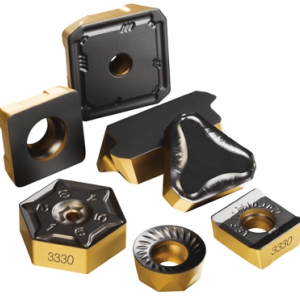

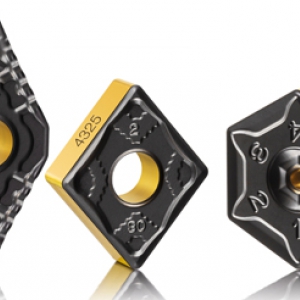

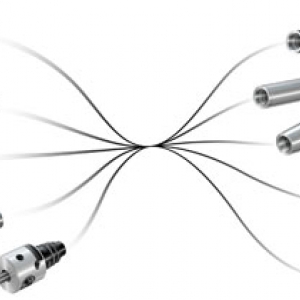

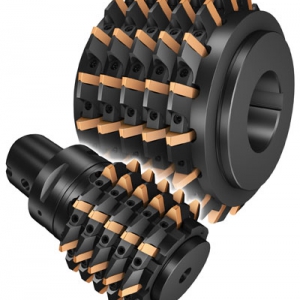

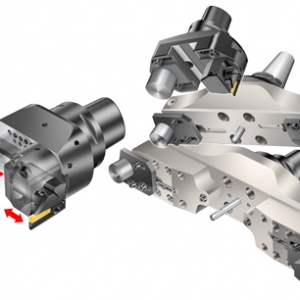

The CoroMill 316 exchangeable-head milling system from Sandvik Coromant is suitable for high-feed facemilling, slot milling, helical interpolation, shoulder milling, profile milling and chamfer milling of components in material groups from ISO P to ISO S. This high performance system is available with internal coolant holes.

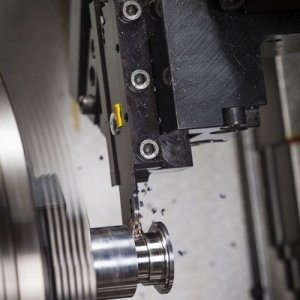

The machining of such materials as heat resistant super alloys, titanium and stainless steels often requires the use of coolant for temperature control and chip evacuation during cutting. Recutting of chips and chip jamming, often lead to poor surface quality, damage to the cutting edge and tool breakage.

By offering an internal coolant solution, with precise positioning of coolant holes to optimize the effect of the coolant jet, CoroMill 316 is able to outperform existing solutions with external coolant, guaranteeing superior chip evacuation and a secure cutting process, according to the company.

The CoroMill 316 system allows machine shops to quickly, easily and accurately switch between various operations such as cutter type, radius variation, teeth frequency, geometry and grade. CoroMill 316 end mills are even suitable for 5-axis milling of flanks which often require tapered tools for stability at longer tool reach.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- facemilling

facemilling

Form of milling that produces a flat surface generally at right angles to the rotating axis of a cutter having teeth or inserts both on its periphery and on its end face.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

PRODUCTS

PRODUCTS