Contact Details

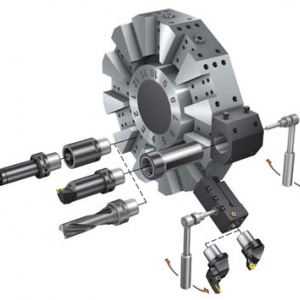

With CoroMill 425, Sandvik Coromant offers an eight-edge finishing tool designed for face milling that greatly improves metal removal rate and tool life in the ISO K application area. Due to its innovative setting system, it is particularly user-friendly.

Sandvik Coromant has introduced CoroMill 425, a finishing tool for the face milling of cast materials. With its eight edges it is ideal for face milling components such as engine and cylinder blocks, axle housings, brake carriers and crankcases made of GCI, NCI and CGI materials. Due to its patented setting system, the tool features highly precise, reliable insert positioning that makes set-up very simple.

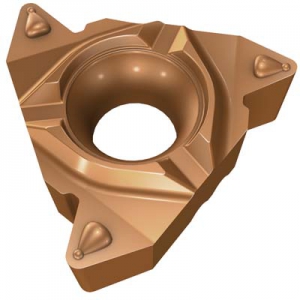

On the CoroMill 425, the same inserts can be used as working or as wiper inserts. The wiper inserts are mounted in cassettes on the face of the tool. The insert version with a 25° entry angle and optimized chamfer is designed to reduce breakouts and burr formation on the workpiece. A choice of wear-resistant GC1010 PVD insert grade for dry milling and K20W grade for wet milling enables especially long tool life in CGI materials.

Related Glossary Terms

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- finishing tool

finishing tool

Tool, belt, wheel or other cutting implement that completes the final, precision machining step/cut on a workpiece. Often takes the form of a grinding, honing, lapping or polishing tool. See roughing cutter.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS