Contact Details

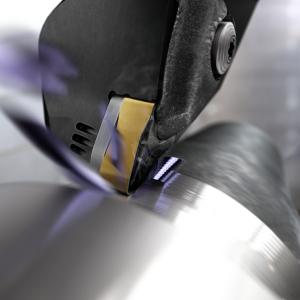

Cutting tool specialist Sandvik Coromant has launched a new milling concept — CoroMill® MR80 — primarily designed for challenging roughing operations in a wide range of face and profile milling applications in steel and stainless steel.

CoroMill MR80 is a double-sided round insert concept with a higher number of inserts compared to regular round insert cutters. It is ideally suited to low depth of cut — up to 3 mm — in face milling and profile milling applications in both steel and stainless steel.

Originally designed for machining cast stainless components such as turbochargers and exhaust manifolds in the automotive sector, this product has been further developed to cater to steel milling applications, which require the security of a round cutting edge — such as the die and mold segment. As a result, CoroMill MR80 is an extremely capable and versatile milling concept that offers both higher productivity and economical machining in a wide range of operations, with no compromise on security.

“The round cutting edge is considered to be the most secure edge for challenging materials as well as tough cutting conditions,” says Sangram Dash, global product application specialist for indexable milling tools at Sandvik Coromant. “Furthermore, the shim offers additional security for the cutter body, protecting against coining deformation and machining accidents, while also securing the insert in the tip seat by restricting micro-movements during cutting.”

An economical solution, CoroMill MR80 features double-sided inserts with 12 indexing possibilities when operated within a 3 mm depth of cut. “That means more parts for each set of inserts,” says Dash. A higher number of inserts on a cutter body also enables a higher table feed and increased productivity. On top of that, the overall security and reliability mean less damage to the cutter body and inserts which, ultimately, helps to cut costs.

Thanks to its lightweight cutting geometry, it is also possible to use CoroMill MR80 as a problem solver in difficult machining situations, even with long overhangs.

“Frequently, due to their intricate shapes, automotive cast stainless components are mounted on a fixture that may not be suitable for higher cutting loads,” says Dash. “And often, in die and mold applications, the cutter must go deep into the mold cavity, mounted on a long adaptor. In both cases, the cutting forces must be limited so that vibration can be avoided. Although CoroMill MR80 is a double-sided negative concept, it works with fairly low cutting forces and is a suitable solution for such applications.”

The CoroMill MR80 assortment offers cylindrical and arbor cutter bodies, with diameters from 32 to 100 mm, 3 to 12 cutting teeth and even pitch and shim protection. All cutter bodies feature internal coolant supply. The double-sided E-L50 inserts offer true and easy indexing (6 + 6), with a 3 mm recommended depth of cut.

Related Glossary Terms

- arbor

arbor

Shaft used for rotary support in machining applications. In grinding, the spindle for mounting the wheel; in milling and other cutting operations, the shaft for mounting the cutter.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

PRODUCTS

PRODUCTS