CoroMill QD Groove Milling Concept

CoroMill QD Groove Milling Concept

Dedicated for groove milling and parting off operations, CoroMill QD from Sandvik Coromant takes care of chip issues with optimized geometries and a unique internal coolant solution.

The main challenge in groove milling is often chip evacuation. Chip issues can harm production efficiency, lower component quality or cause tool breakage, especially when machining narrow and deep grooves. Dedicated for groove milling and parting off operations, CoroMill QD from Sandvik Coromant takes care of chip issues with optimized geometries and a unique internal coolant solution.

The insert geometry deforms chips to a more narrow shape than the groove, and then the chips are flushed out by coolant. This technology, combined with long and predictable tool life, makes CoroMill QD a reliable solution for secure and trouble-free production processes, according to the company.

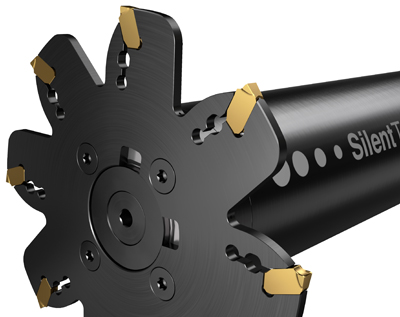

A range of new adapters complements the new cutters. These adapters enable use of CoroMill QD cutters regardless of whether the preferred machines are small- to medium-sized machining centers, large machining centers or multitask machines. Silent Tools adapters are available for long overhang machining.

The internal coolant is based on a four-channel delivery solution from the adapters to the cutter. By implementing this solution on the new adapters for CoroMill QD, coolant delivery into the groove is achieved.