Cutting Tools with Diameters in Fractional Inches

Cutting Tools with Diameters in Fractional Inches

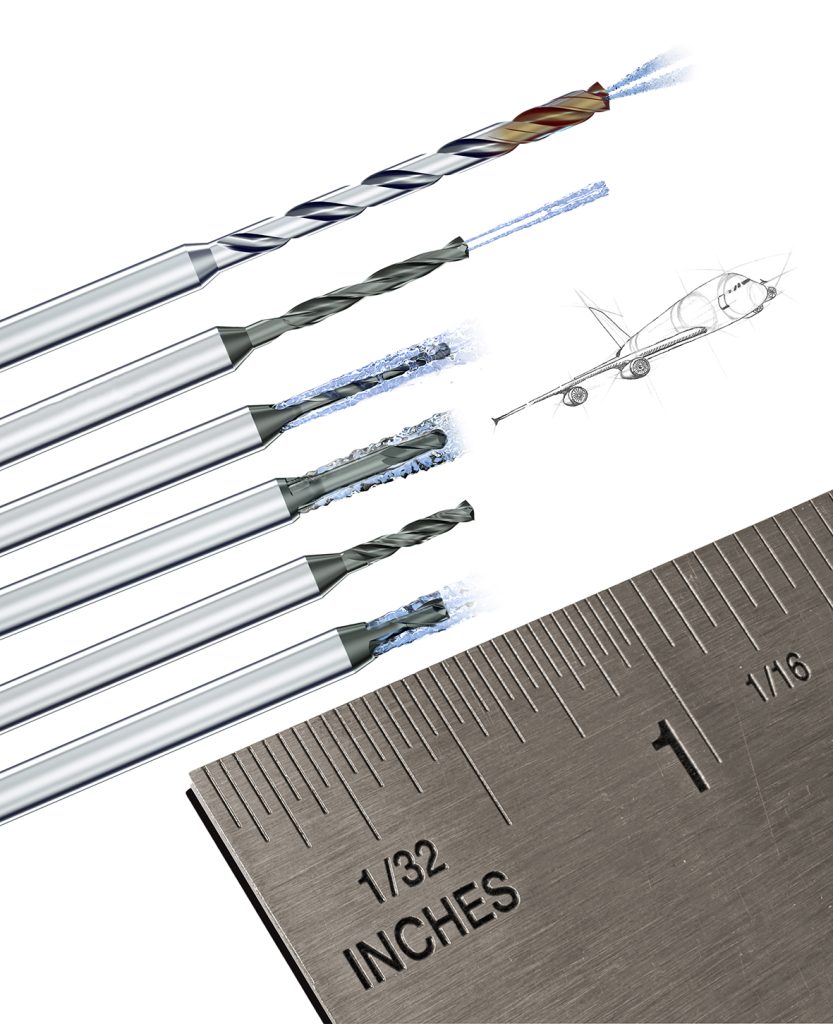

The need for such dimensions is increasing that's why Mikron Tool has introduced a fractional inches diameter range for a large assortment of its drilling and milling cutter families. The selection is focused on materials such as stainless steel, titanium and superalloys. The range includes micro drills and micro mills of .016" and extends up to diameter .250". From the high-performance small Crazy Drill Steel up to the cylindrical micro end mill Crazy Mill Cool, Mikron Tool offers a tool range that will satisfy most every need in a multitude of projects.

The Swiss cutting tool manufacturer Mikron Tool expands its offering and now provides tools with diameters in fractional inches, starting from 1/64" up to 1/4" depending on the product line. The United States is not only an industrially and technologically advanced nation, but is also at the forefront in many high-tech industries such as aerospace. Therefore, many measuring elements in this sector are expressed in U.S customary units (inches). Not only in the United States but worldwide.

The need for such dimensions is increasing that's why Mikron Tool has introduced a fractional inches diameter range for a large assortment of its drilling and milling cutter families. The selection is focused on materials such as stainless steel, titanium and superalloys. The range includes micro drills and micro mills of .016" and extends up to diameter .250". From the high-performance small Crazy Drill Steel up to the cylindrical micro end mill Crazy Mill Cool, Mikron Tool offers a tool range that will satisfy most every need in a multitude of projects.

Every tool has specific characteristics. For example internal cooling channels, as in the case of the deep hole drill CrazyDrill Cool SST-Inox, allow efficient chip evacuation and thus ensure high performance machining even at a drilling depth of 40 x d. Or the special cutting geometry of the plunge mill CrazyMill P&S allowing perpendicular plunging with subsequent milling into solid material and so perfect for slots and pockets in minimal space. This range starts from a diameter of .039" (1 mm) or 1/16" for fractional sizes.