Contact Details

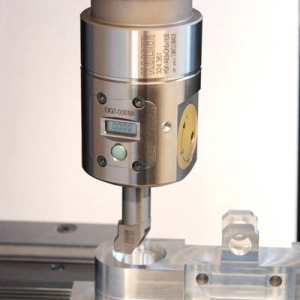

BIG Kaiser Precision Tooling Inc. introduces a budget-friendly benchtop tool presetter equipped with a 5.7-inch color LCD touch screen and camera. As an upgraded model of the popular DIASET, manufactured by Innotool (Austria), this vision-based camera version enables one-touch angle, radius, diameter and length measurements. An optional incident light allows for inspection of cutting edges for built-up edge, flank wear or fractures.

The DIASET is built with a stable measuring column and base made out of mineral cast. This strong foundation ensures extreme rigidity and excellent temperature resistance for high repeatability and positioning accuracy of .0001". These impressive capabilities on an entry-level presetter are also supported by horizontal and vertical slides that smoothly move along hardened and precision ground guideways, both with pneumatic locking mechanisms and foot pedal control.

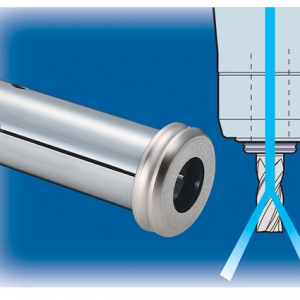

The high-precision rotating spindle allows a guaranteed accuracy of runout measurements to less than .0008" T.I.R. and is available with either integral ISO50 or ISO40 taper spindles. Reduction adapters are available for other common interfaces (ISO, HSK, KM, Polygon). Many combinations of max diameter/max length are available to perfectly suit your measuring needs and budget.

Additionally, two built-in USB ports for simultaneous external data saving and label printer connection, as well as internal storage of up to 99 reference points, means investing in the DIASET Camera Type will dramatically reduce the chance of human error in tool preparation.

Related Glossary Terms

- built-up edge ( BUE)

built-up edge ( BUE)

1. Permanently damaging a metal by heating to cause either incipient melting or intergranular oxidation. 2. In grinding, getting the workpiece hot enough to cause discoloration or to change the microstructure by tempering or hardening.

- flank wear

flank wear

Reduction in clearance on the tool’s flank caused by contact with the workpiece. Ultimately causes tool failure.

PRODUCTS

PRODUCTS