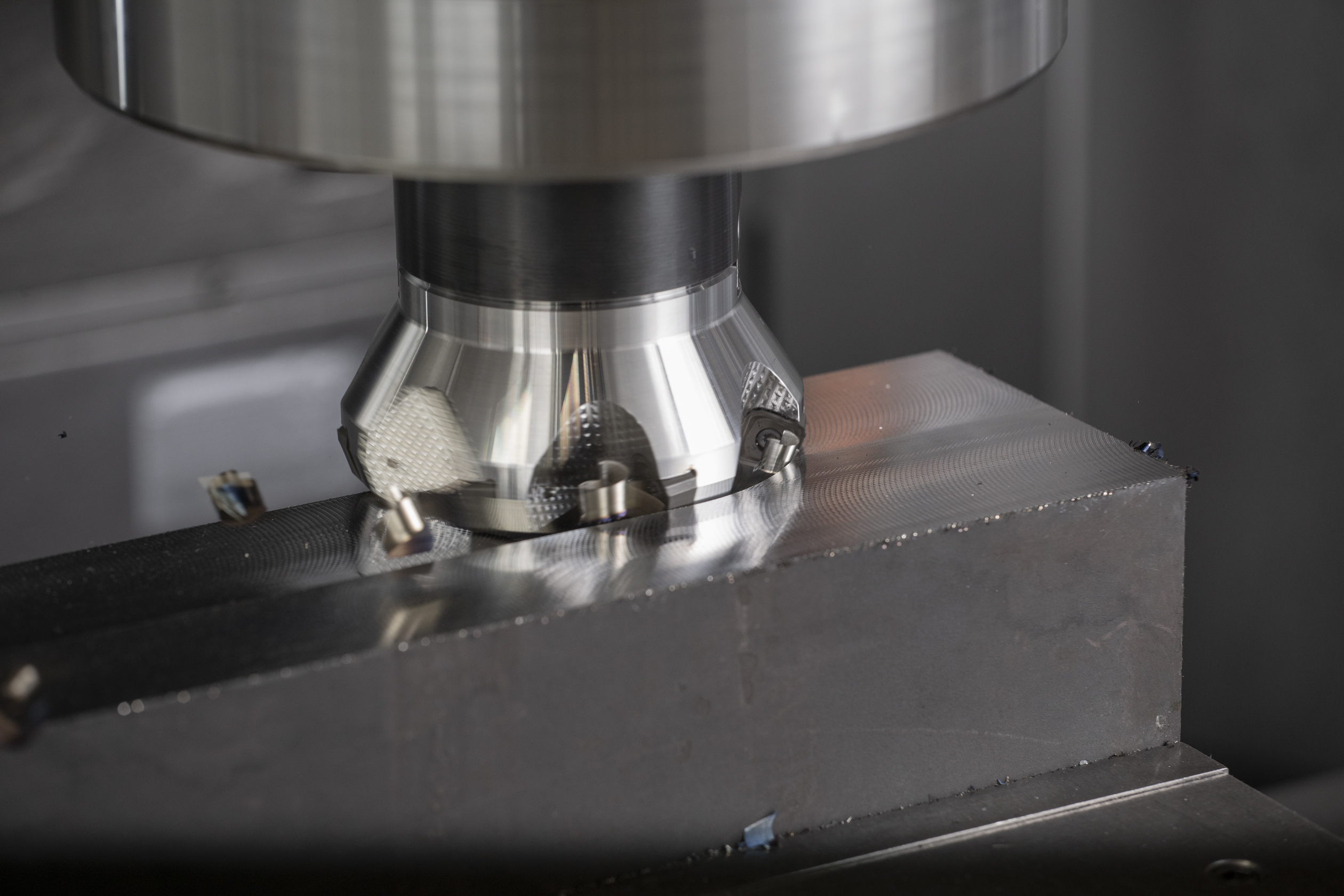

Double Quattromill14 Facemilling Cutter

Double Quattromill14 Facemilling Cutter

Shops with lower horsepower machines can maximize their facemilling operations with the new Seco Tools Double Quattromill14 facemilling cutter. For cost effectiveness and increased depths of cut in roughing, semifinishing and finishing, the cutter uses double-sided inserts with eight cutting edges and represents a smaller version of the company's Double Quattromill 22 cutter, which targets those machines with higher horsepower and torque.

Shops with lower horsepower machines can maximize their facemilling operations with the new Seco Tools Double Quattromill14 facemilling cutter. For cost effectiveness and increased depths of cut in roughing, semifinishing and finishing, the cutter uses double-sided inserts with eight cutting edges and represents a smaller version of the company's Double Quattromill 22 cutter, which targets those machines with higher horsepower and torque.

The Double Quattromill 14 achieve depths of cut up to 0.236" (6mm) in its 45° lead angle version and up to 0.315" (8mm) in its 68° version. For better chip thinning and higher feed rates, the 45° angle excels in weak or unstable fixturing. With better clearance to avoid sidewalls or part fixturing than the 45° degree angle, the 68° angle reaches high depths of cut with the same size inscribed circle (IC) on the insert. The Double Quattromill 14 extends tool life while it lowers cutting forces and machine power consumption with its extremely free cutting qualities.

Available in standard or close pitch and in metric or inch versions, Double Quattromill 14 cutter bodies come in fixed-pocket and cassette styles. For enhanced chip control and evacuation as well as durability, Seco applied its new surface texture technology to the cutter's body flute surfaces.

To provide flexible options, the Double Quattromill 14 comes in three insert ranges with various edges and grades. The ME10 geometry works with sticky materials such as titanium and stainless steel. The M10 geometry includes sharper edges and smaller T lands for reduced cutting force that excels at lower horsepower levels, working with sticky materials, some tool steels and super alloys. The M16 provides the best edge protection of the three insert geometries when machining abrasive materials such as steels, tool steels and cast irons.