Contact Details

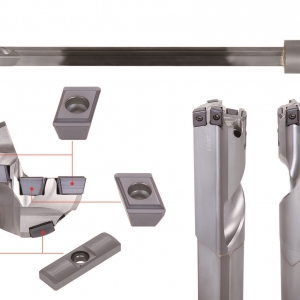

Tungaloy’s DrillMeister exchangeable-head drill line now includes new TID-type drills in cylindrical shanks that accommodate drill head diameters ranging from 10.0 mm to 19.9 mm (0.398" to 0.783").

DrillMeister features a unique self-locking interface that interlocks between the drill head and shank body, enabling a simple and quick tool exchange. Operators can replace the drill head without having to remove the drill body from the adapter or remeasure tool offset vales, thus saving time. The drill head can be easily assembled while remaining on the machine. The drill body incorporates strong helical flutes with polished surfaces for reliable chip evacuation. This feature is especially important in deep hole drilling applications where smooth chip evacuation is vital.

The new TID drills are offered with a cylindrical shank. A precision-ground cylindrical shank with no flats provides a close runout accuracy and high torque transmission when clamped with a full surface contact in a high-precision collet chuck, milling chuck or hydro-chuck holder.

In addition, all the new drills have longer shank lengths (LS) than the existing TID drill lines. Longer shanks enable more flexible adjustment of a drill overhang length when being clamped in the holder.

Holemaking operations often require drills with a flute length that is way longer than the hole depth to be machined, just to avoid a fixture or structural interference. The new TID drill can provide an extended drill overhang by shifting out the shank clamping position in the holder, while retaining a minimum flute length necessary for smooth chip evacuation and tool stability.

Enhanced with the new drill line, DrillMeister provides customers with high productivity, reduced of tool inventory and elimination of regrinding costs.

At a glance:

Available drill diameters range from 10.0 mm to 19.9 mm (from 0.398" to 0.783") in increments of 0.1 mm (0.004") in 3.5xD-, 6xD- and 8xD-length bodies

Strong helical-flutes with a polished surface ensures smooth chip evacuation

Unique self-locking interface enables a simple and quick tool changeover

Clamping design with a fatigue-resistant receptacle on the drill body allows increased number of drill head changes

Margined cutting edges provide close hole tolerances equivalent to those of solid carbide drills

No reconditioning is needed – leading to reduced tool inventory and management, as well as elimination of regrinding costs

Available with cylindrical shanks most suited for use with high-precision collet chucks, milling chucks and hydro-chuck holders

Long shank lengths enable the extension of drill overhang while retaining the minimum flute length

Total of 45 drill bodies to be added

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS