Contact Details

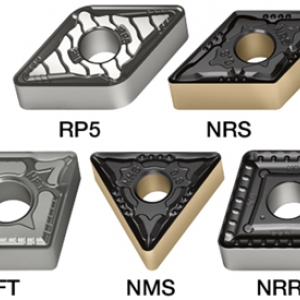

Walter has launched a major extension of its turning geometry program with new products that bring Walter precision and reliability to a range of new applications. Extensions include the FM4 positive inserts. Engineered for finishing stainless and high temperature alloys (ISO M, S), these inserts have excellent chipbreaking capabilities at low feed rates and low cutting depths. They are available in grades WSM10S, WSM20S and WSM30S.

Walter’s RM4 positive inserts are targeted at stainless and high-temperature alloys (ISO M, S) for roughing and medium machining operations. They are available in grades WSM10S, WSM20S, WSM30S and WMP20S.

The new FP6 positive inserts excel at finishing steels (ISO P) and provide superior chip control. They are available in grades WPP10S and WPP20S. The FP6 is a productive alternative to FP4 and MP4 and replaces PS5 in steel applications.

Walter’s FK6 positive inserts, available in grades WKK10S and WKK20S, are engineered specially for finish to medium machining. They are an alternative to MK4 and replace PS5 in iron applications.

Importantly, the Walter turning program extension also includes positive wiper inserts for PF and PM geometries. These inserts provide high surface quality and high feed rates. They also give users the flexibility of choosing to maintain their current surface quality with double the feed rate or 50 percent lower surface roughness with their current feed rate.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS