Contact Details

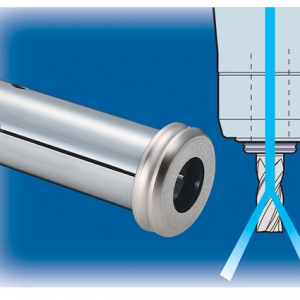

BIG KAISER announces its HDC Straight Shank holder to the market, used for increased versatility. The slim design provides superior balance, concentricity and is suitable for reaching into confined areas.

Hydraulic chucks are excellent toolholders for machining processes that require high accuracy such as drills, reamers, ball mills, endmills, diamond reamers and grinding tools. They are for high-precision machining in automotive, aerospace, medical, and die and mold.

HDC Straight Shank super slim holders can be clamped into other base holders to extend overall reach of the tool assembly and avoid the need for special tools. The slim nose design provides the necessary clearance for use with deep workpiece access, making them an ideal solution for 5-axis tool holding requirements.

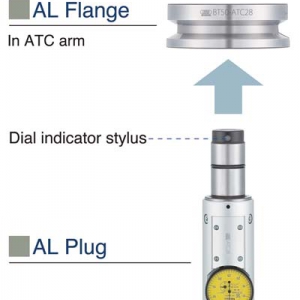

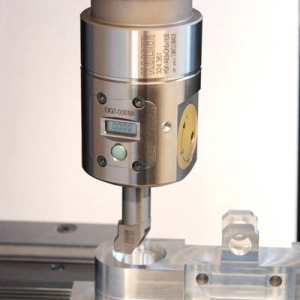

The BIG KAISER HDC toolholders are simple to use; only one hex key wrench is needed to clamp or loosen the cutting tool, making tool changes fast and easy without special equipment. Every HDC toolholder is guaranteed to 0.00012” TIR at 5 times diameter. Optional straight collets can also be used to increase the range and versatility of each size.

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- total indicator runout ( TIR)

total indicator runout ( TIR)

Combined variations of all dimensions of a workpiece, measured with an indicator, determined by rotating the part 360°.

PRODUCTS

PRODUCTS