hyperMILL CAM

hyperMILL CAM

OPEN MIND Technologies AG introduces the new version of its hyperMILL CAM solution.

OPEN MIND Technologies AG introduces the new version of its hyperMILL CAM solution. Highlights of the 2012 version include automatic programming options for rectangular pockets, optimisations for 3D roughing and new strategies for 5axis machining of impellers and blisks. Other changes improve calculation times and programming times.

The new "adaptive pocket" machining mode allows for automatic programming of rectangular pockets. Within a machining job, classification occurs automatically in closed and open pockets and rectangular levels. According to the various accessibility conditions for the tool and relative sizes of the tool and pocket, hyperMILL automatically selects the most suitable machining method: spiral, contour-parallel or peeling. The optimised clearing movements take place in long, straight paths with constant cutting conditions. Critical full cutting areas are parameterised separately, allowing control over feedrate values and reduced production times.

The ways in which machining times have been shortened are both simple and ingenious: During 5axis shape offset machining with hyperMILL, users now avoid redundant movements thanks to the new axial sorting option that makes it possible to divide machining by area. This allows corners or pockets, for example, to be machined individually one after another. The user can decide whether to create toolpaths with offset level sorting or axial sorting.

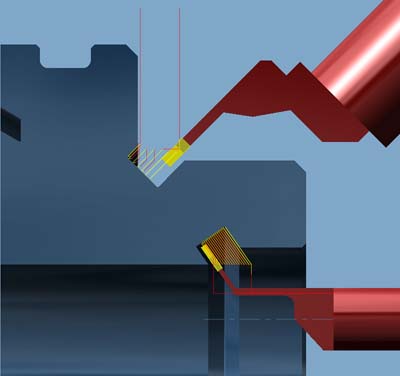

There are several new features for roughing in the 5axis impeller and blisk package. For machining of impellers, for example, it is now possible to divide the machining region into a left and right pocket between the main blade and the splitter. This new option means that these areas can now be machined with different tools in a targeted manner.

The flank mode during roughing enables swarf cutting near blade surfaces. The user can decide whether to use the swarf mode for every step or just for the last step. This extension results in a consistent stock allowance for finishing. Production time can also be reduced here as preliminary finishing can be skipped.

hyperMILL 2012 supports tapered tools for 3D ISO machining — including automatic collision avoidance. In the process, the entire tool is checked for collisions against the model, which ensures high process reliability. Tapered tools offer more stability, reduce tool vibrations and improve surfaces simultaneously.

For turning operations, hyperMILL functionality has been extended to include inclined grooving. This is why offset tools can now also be used. The tool database has therefore been expanded to include these recessing tools.

Pocket milling has been improved in the 3D roughing area. As a result, for the machining of pockets, the ramp is moved continuously in one direction. The pocket is then cleared from the outside" Advantage: Thanks to the continuous inward movement of the ramp, the tool path is optimised, and zig-zag movements are avoided.