Inch Version of the Helical AD Shoulder Mill

Inch Version of the Helical AD Shoulder Mill

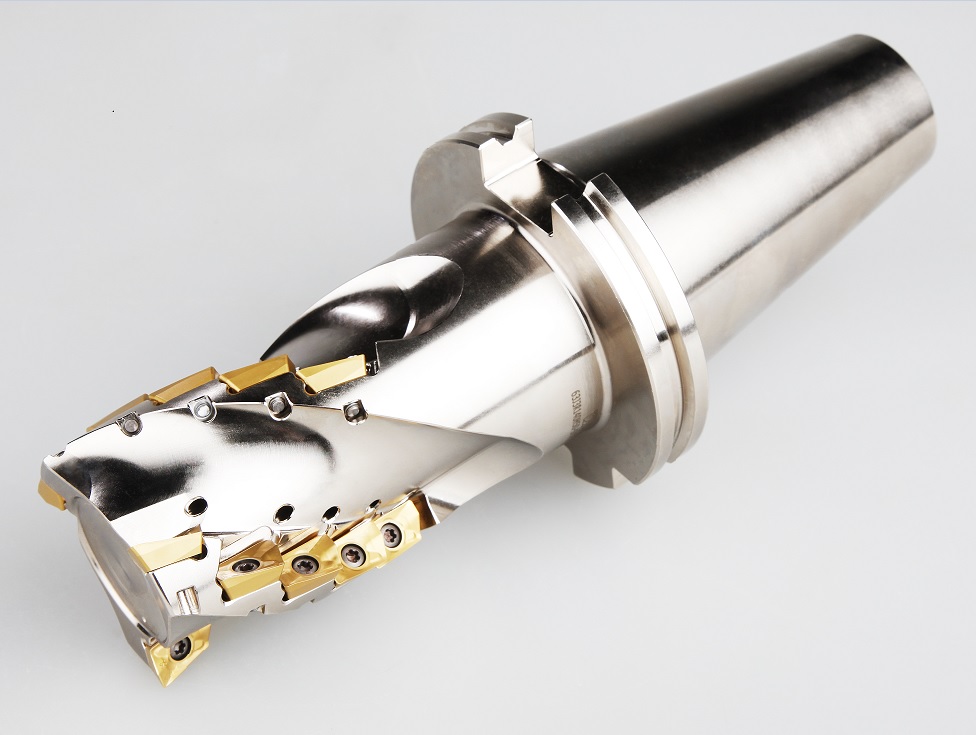

The inch version of the popular Helical AD for roughing applications is now available. Offering a DOC up to 3.150", the cutters are suitable for use with the Pramet range of versatile ADMX 16 inserts and support medium machining of most engineering materials, including cast iron, stainless steel, aluminum alloys and superalloys.

The inch version of the popular Helical AD for roughing applications is now available. Offering a DOC up to 3.150", the cutters are suitable for use with the Pramet range of versatile ADMX 16 inserts and support medium machining of most engineering materials, including cast iron, stainless steel, aluminum alloys and superalloys.

The large clearance between the cutting teeth, combined with internal coolant delivery, promotes efficient chip evacuation. The axial clamping of inserts on the end teeth increases milling stability. This helps to minimize noise and vibration which, in turn, helps in reducing tool wear. The special surface treatment of the body is nickel plated for a higher resistance to corrosion and lower abrasion.