Contact Details

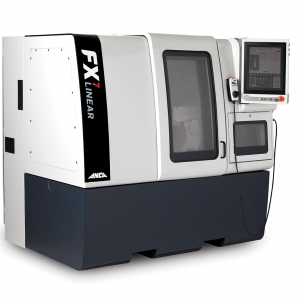

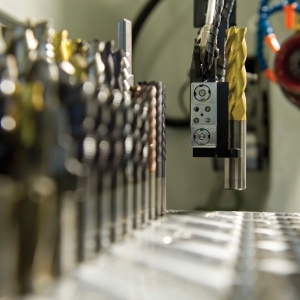

ANCA Inc. custom-designed and built a new industrial robot loader for exhibition and demonstration purposes and is currently not available for sale.

Pat McCluskey, ANCA’s co-founder and lead designer on the project said: “We recognize that as the market moves towards greater automation, providing a low-cost solution for tool loading was something our customers would welcome. I've been asked how it is that ANCA is able to develop its own industrial robot. For us, it is a logical extension for our company whose strength is having multi-disciplinary technical expertise and an intimate knowledge of the CNC market. It's actually a relatively simple task to develop the mechanical aspects of an industrial robot, but to make it function successfully you better be expert in designing your own CNC system, digital servo drives and core software--skills that are ANCA's unique strengths in the tool grinding industry.

“The ANCA robot does not use a separate free-standing controller. The control system software actually runs concurrently within the machine's CNC core software and uses the machine's operator panel and hand-held pendant to perform the teaching. If you can use an ANCA tool grinder, you can use an ANCA robot as well, and our engineers can easily service your ANCA robot. We pride ourselves on providing customers with a complete ANCA machine solution and that is why we have invested in developing our own industrial robot.”

According to an ANCA spokesperson, “ANCA is known for being the market leader, pushing the boundaries of existing technology. We develop new products and innovations that continue to raise the bar of what a CNC tool and cutter grinder can deliver for our customers. Coupled with this, our commitment to investing in creating our own technology provides a complete machine solution and guarantees ANCA’s promise of quality and expertise.”

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

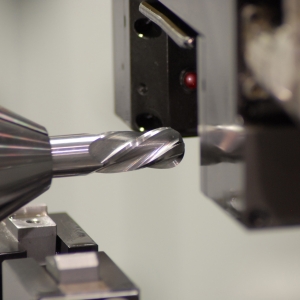

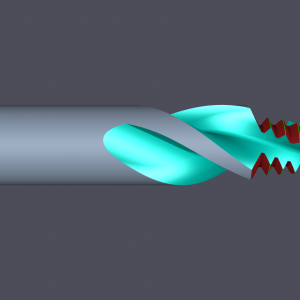

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- industrial robot

industrial robot

Robot designed for industrial use. Primarily used as a material-handling device but also used for changing tools, assembling parts, and manipulating special tools and measuring devices. Depending on design, an industrial robot can be programmed to perform a task by means of a controller, or it can be “walked” through the required movements by utilizing a digitizing system that translates movements into commands that the robot can be “taught.” See robot; teaching pendant.

PRODUCTS

PRODUCTS