JomaX Milling Center

JomaX Milling Center

Manufactured by Jobs (Piacenza, Italy), JomaX is a family of big, high-power milling centers with a configuration of both vertical and horizontal axes.

Manufactured by Jobs (Piacenza, Italy), JomaX is a family of big, high-power milling centers with a configuration of both vertical and horizontal axes. "The features of JomaX machines improve the competitiveness of our customers in many different fields: from precision machining to heavy mechanics, such as the manufacturing of mold holders, large sized molds or large structural parts in titanium," says Antonio Dordoni, Sales, Marketing and Services Director of Jobs SpA.

The JomaX milling center family with high power includes three models: the JomaX 265, the JomaX 261, both with a mobile gantry, and the JomaX 269 with mobile column. The main feature that makes the JomaX family very competitive in the large machines sector is its great operating flexibility thanks to an extensive customization of the installation. In fact, all of these machines can be equipped with a range of accessories and devices, step by step or in subsequent periods. Static palletization systems allow pendulum type manufacturing, while mobile pallet changing systems allow connecting several machines in order to manufacture large size parts.

JomaX milling centers can be equipped with a modular tool changer with rack, that has a high capacity (up to 400 tools for each machine), and eventually with robotized movement devices and measurement and control accessories integrated in the structure of the machine. In addition, milling heads with a BUSS automatic changer will be included to guarantee the integrity and precision of the manufacturing cycle from roughing to superfinishing in only one positioning of the part.

Other functional features of the JomaX machines are the built-in head magazine/tool magazine group positioned in areas far from the operator but easy to control and its very compact and functional size to obtain higher productivity. Furthermore, the morphology of the work area allows an easy expulsion of the chips towards the conveyors for a fast and efficient removal of them.

On the other hand, the closed working area guarantees the operation of the machine in a completely safe way. The JomaX 265 milling center with vertical z-axis has a medium-big sized mobile gantry structure, designed for adapting to a large number of customer configurations depending on the applications and specifications requested. It is also capable of offering, besides a powerful motor spindle, dynamic versatility that allows for higher speeds without the loss of precision or increased levels of vibration.

"The JomaX 265 is characterized by maximum structural rigidity, high volumetric precision, high dynamics in acceleration and speed and a high degree of automation for a customized production," states Dordoni. "Their typical application fields range goes from aeronautics, automotive, and general mechanics, up to the manufacturing of large carpentries for the energy sector. An example is the manufacturing of structures for large mechanical presses."

The modular design of the three linear axes of the JomaX family of gantries allow making machines with larger or smaller dimensions, according to the specific application requirements, from a base model of X=5000, Y=3000, Z=1250mm. The installation that has been recently presented in the "The Jobs Milling Show" event is based on the vertically mobile crossbeam: JomaX 265 MB.

The dimensions of this mobile gantry are impressive: longitudinal travel of 28 m, transversal travel reaches 6.5 m and vertical travel of 3.5 m made up of the two movements of the crossbeam and the RAM; more precisely: vertical mobile transverse stroke 2000mm, RAM stroke 1500mm. The machine is equipped with three milling heads for 3 and 5 axes manufacturing: a first head with 3 axes (power of up to 53 kW and spindle speed of 3000 revolutions/min), a second 90 degree head (power of 30 kW and spindle speed of 2800 revolutions/min.) and a T6K-P twist head ( power of up to 53 kW and spindle speed of 3000 revolutions/min ).

The heads are automatically interchangeable thanks to the BUSS (Basic Universal Spindle System) head changing system patented by Jobs. On one hand, JomaX 265 MB is very efficient for heavy milling conditions (from which the power, torque and sizing of this machine are derived) and, on the other, it can carry out roughing and finishing on sculptural surfaces.

"This has required the combination of high power with superior dynamics: high accelerations in spite of the size of the machine and a movement capacity that is close to high speed machines," explains Dordoni.

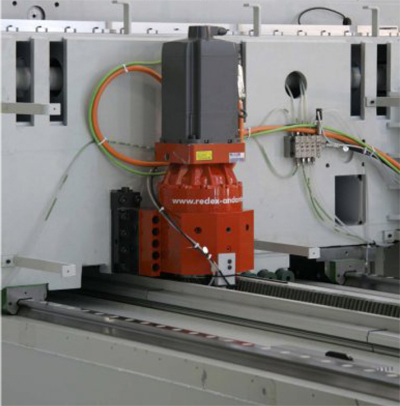

For JomaX 265 mobile gantry milling machines with vertical z-axis, Redex gearboxes are used in the control of the linear axes and in the kinematic chain of the spindle. "We use axes gearboxes with double pinion to completely cancel backlash and for spindle transmission use a two speed gearbox," says Maurizio Ferrari, Director of the Mechanical Engineering Department.

Previously, gearboxes were used with mechanical preload (using a torsion bar) and a single motor per axis. After a recent revision of the machine, Redex gearboxes units with twin drive and an electronic backlash cancelation are now utilized.

"We have been using Redex products for many years," Ferrari stresses. "We initially considered Redex's offer interesting when it was launched with a complete double pinion gearbox unit that was already built with the mechanical preload by using a torsion bar. This allowed us to manage the axis with only a single product and to work with more certain assembly times. At that time, Redex was practically the only company on the market capable of offering products adapted to our requirements. Other suppliers then arose with similar products but, in the case of the JomaX 265 MB family, and more generally for all of the JomaX family, we believe that Redex products continue to be the most suitable for us."

Later, when the development of the technology allowed electronic backlash cancelation, Redex became much more flexible, introducing a new family of gearboxes. As an advantage, these gear units allow selecting the preload values according to application, unlike the torsion bar that foresees a fixed preload. Therefore, Jobs has adopted the Redex solution with a double motor.

"This solution has now been extended in two ways," Ferrari further explains. "A unique double pinion gearbox (DRP) is still adopted on the X-axis since it has a single very robust housing but integrating two motors. On the contrary, in Y and Z axes, we use two separate gear units assembled into two different housings of spheroid cast iron (KRPX) that obtain important advantages during the assembly.

"Redex solutions with double motors permit us to apply the technology of the electronic backlash cancelation using a single preassembled group," Ferrari adds. "A rigid and compact assembly can be made in this way. Even in the version with only one pinion, the 'flanged' solution is very easy to apply.

"Twelve years ago we chose Redex because it was, in fact, the only one on the market that proposed a preassembled group," Ferrari says. "Other suppliers still prefer to manufacture gears and gearboxes themselves, while our industrial policy is to buy everything ready made, looking for synergies with our partners. From this point of view, Redex is a company that is very open to co-design, supporting each other in the sizing verification phase. When we have to choose a gear unit, we talk to Redex engineers that help us choose the type of gearbox, the size, the module, and the reduction ratio in order to obtain exactly the functional characteristics of our machine."

Redex's two-speed gearbox is used in the JomaX family milling machines, improving the performances of the spindle motor. Having a gearbox between the motor and the spindle helps to obtain the maximum speed or the maximum power exactly when needed. High speed can be reached with low torque ratings when light manufacturing is made with small tools, or high torque ratings with low speeds, for example, in roughing with big tools. Redex has developed a very innovative product, which is called RAM Hit. It is a cylindrical shape product without overhanging parts and with a motor coupling designed together with the leading motor manufacturers. This solution allows having an optimum assembly inside the RAM, thanks to its regular shape.

Furthermore, Redex is different than other suppliers thanks to a complete catalogue of two speed gearboxes designed for high performance machine tools, characterized by an extremely high transmitted torque. The Hit RAM (High Torque) has been designed in collaboration with the main motor spindle manufacturers so that a perfect inline integration can be achieved between the motor and the spindle inside the RAM. This new design gives the machine big improvements in reliability and performance. The torque rating transmitted at low speed is approximately the double with respect to the previous gearbox generations due to a completely new design of the planetary gear train that is the "heart" of the unit. The RAM Hit has no electronic device internally thus improves the reliability and simplifies maintenance.

The housing has been designed so that the limit switches of the speed changer can be installed outside the spindle line, making possible replacements easier and faster. The two speed gearbox is integrated inline inside the RAM, between the water cooled motor and the tool-holder spindle. The gearbox can use the same coolant of the motor and a dedicated lubrication circuit, greatly simplifying the design of the machine's installations. The gearbox is hydraulically activated using one of the several circuits normally available in all types of machine tools.

A main feature is the hollow bore offering a very big diameter (from 29 to 54mm according to the model) capable of containing both the draw bar and the other services necessary for the spindle, such as the high pressure oil circuit for the lubrication of the tool and chip removal. In spite of very high rotation speeds (up to 15,000 revolutions/minute for the smallest size), the vibrations and noise are very low thanks to a precise balancing process of all components in rotation.

"Redex has developed solutions that fit perfectly to the requests of the machine tool sector and in particular our specific requests," Ferrari concludes. "While other manufacturers offer more general products, Redex proposes a line of gearboxes designed specifically for application in machine tools, especially for heavy applications. To date, Redex products behave exactly according to our expectations, confirming the validity of our initial choice."