Contact Details

Because of its high strength-to-weight ratio, titanium remains in high demand for precision components such as turbine blades in aircraft engines and power plants and frame components in aircraft structures and racecars. Shops know machining titanium and other high-strength/high-temperature alloys is a significant challenge, unlike milling steels or aluminum.

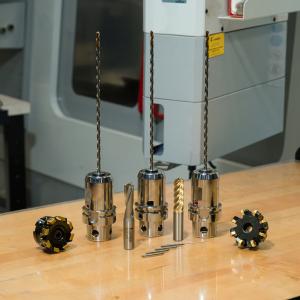

With approximately 25 percent longer tool life, the new KCSM30 milling grade from Kennametal directly reduces cost-per-part for shops working on titanium, according to the company. With a fine-grained carbide substrate for strength and stability together with a TiAlN PVD coating for excellent wear resistance, not only are tools lasting longer, shops are also able to increase cutting speeds, up to 230 sfm (70m/min).

Due to titanium's high strength, thermal management is extremely important in managing and prolonging tool life. KCSM30 is also available in Kennametal's proprietary Beyond Blast composition, where integral coolant channels deliver coolant through the insert precisely to the cutting edge under the chip, where it does the most good reducing heat and friction while increasing productivity. In addition, coolant is only delivered in the insert quadrant that is doing the actual cutting, allowing the inserts remain indexable for maximum use.

Demand for higher-strength, higher-performance components in the world's critical industries will only continue to expand, along with the pressures on manufacturers to increase quality and reduce costs. Available in face milling, copy milling, and shoulder milling platforms, KCSM30 from Kennametal is reportedly an effective choice for shops seeking to improve productivity.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS