KYHK15B Ceramic Turning Grade

KYHK15B Ceramic Turning Grade

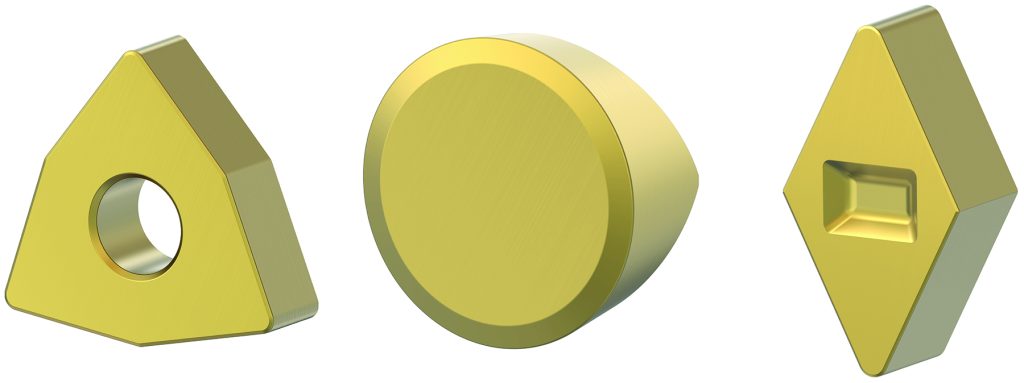

KYHK15B provides excellent edge stability, high chipping resistance, and a PVD gold coating makes wear progression identification very easy. From smooth and varying depths of cut to heavy depths of cut, KYHK15B can be an economic alternative to PcBN inserts.

Kennametal has introduced its latest ceramic turning grade, KYHK15B™, designed to deliver increased productivity and lower cost per edge in hard turning operations. The new grade provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys, and cast iron, as well as maximum tool life and wear resistance for the most demanding turning applications.

A broad range of styles, sizes, and edge preparations are available. These include the most popular styles of double-sided roughing and finishing inserts for predictable, cost-effective machining.

"KYHK15B provides excellent edge stability, high chipping resistance, and a PVD gold coating makes wear progression identification very easy. From smooth and varying depths of cut to heavy depths of cut, KYHK15B can be an economic alternative to PcBN inserts," says Robert Keilmann, Product Manager, Kennametal.

Depending on the surface requirement and the type of cut, the ceramic grade KYHK15B can be an economic alternative to PcBN inserts when machining hard materials >48 HRC.

KYHK15B builds on an existing line of high-performance ceramic turning grades, providing manufacturers a productive solution for hard turning applications even in varying or heavy depths of cut.