Mach TM

Mach TM

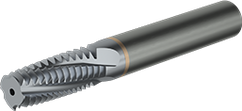

The Vargus Mach TM is a high-performance thread milling tool engineered to enhance machining productivity and efficiency. Designed with advanced features, it is ideal for demanding applications requiring precise threading and superior surface finish.

The Vargus Mach TM is a high-performance thread milling tool engineered to enhance machining productivity and efficiency. Designed with advanced features, it is ideal for demanding applications requiring precise threading and superior surface finish.

Key Advantages:

-

High Feed Rate: Allows for more material removal per flute.

-

Reduced Machining Time: Significantly shortens cycle times.

-

Extended Tool Life: Enhanced durability for prolonged use.

-

Excellent Surface Finish: Ensures superior finish quality.

Features:

-

Improved Cutting Edge & Reinforced Geometry: For handling high loads.

-

Coolant Thru Design: Enhances chip flow and surface finish.

-

Large Core Diameter: Increases stability.

-

Additional Flutes: Enables higher feed rates.

-

Advanced Surface Treatment: Strengthens cutting edges and improves finish.

-

Optimal Flute Length: Provides higher rigidity and efficient chip evacuation.

For more details, visit the Vargus Mach TM page.