Mastercam Mill

Mastercam Mill

Maintaining climb and conventional machining is crucial for surface finish and tool life. Controlling Climb and Conventional Cutting for Morph, Parallel, Unified, Project Curve, and Flow toolpaths now provide constant control of climb or conventional cutting even while in complex areas that would require use of both sides of the tool.n

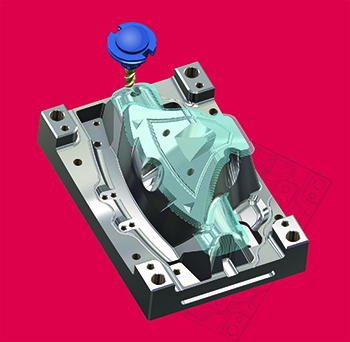

Mastercam Mill offers expanded machining flexibility and an increased emphasis on speed and automation. Multiaxis features, 3D enhancements, and 2D high speed toolpaths combine with dozens of additional new enhancements in a software package intended to improve shop floor productivity.

Here are some of the significant highlights and new functionality in Mastercam Mill:

Multiaxis Improvements

Maintaining climb and conventional machining is crucial for surface finish and tool life. Controlling Climb and Conventional Cutting for Morph, Parallel, Unified, Project Curve, and Flow toolpaths now provide constant control of climb or conventional cutting even while in complex areas that would require use of both sides of the tool.

The new 3+2 Automatic Roughing toolpath automatically makes multiplane 3-axis toolpaths for roughing. Mastercam analyzes the model and stock, and then creates a roughing toolpath. Mastercam calculates the remaining stock and computes a new toolpath. This continues until only a defined amount of stock remains, and results are all contained within one toolpath.

Multiaxis Roughing has been enhanced and renamed to Multiaxis Pocketing and includes new options such as undercut roughing, wall finishing, and floor finishing. Multiaxis Pocketing provides greater control of the tool contract point and machining angle when using Accelerated Finishing® tools and ensures that you get the best possible motion.

The new Unified Multiaxis toolpath allows you to select multiple pieces of input geometry to generate the toolpath pattern. Then, using those geometry choices, the toolpath picks the best algorithm to calculate the path.

3D Enhancements

Mastercam's 3D High Speed Blend toolpath includes many enhancements including the ability to keep created passes equidistant in 3D by adding cuts in steep areas, the capability to set the exact number of cutting passes, reverse cutting direction, confining curves to Tool tip or Tool contact point, as well as two new methods in the Cut method options. By applying Automatic and Custom Angles to Raster Toolpaths, Mastercam now automatically sets different angles to maximize the length of the cut pattern and/or minimize the connecting moves.

2D Enhancements

Advanced Drill, a new toolpath, is a customizable multi-segment drill cycle that is useful for spot drilling, deep hole drilling, and back spot facing. Each segment of the drill cycle can be defined in a table, and for each segment, you can customize any or all conditions. The new Chamfer drill uses tools with a tip angle and chamfers holes after calculating the correct depth based on the desired width or depth. It also allows you to select holes of different diameters or sizes—or that lie in different planes—and machine them in a single operation with a single tool.

Additional Improvements in Mastercam Mill that benefit efficiency include:

- Improved toolpath processing time and surface accuracy for many Multiaxis toolpaths.

- Toolpath Hole Definition has multiple new enhancements.

- A new function, Check Tool Reach, can check your tool and holder against selected model geometry to view where the tool can and cannot reach.

- In 2D Dynamic Mill, users are now able to skip pockets based on tool diameter or pocket size.

- Contour enhancements such as additional Spring pass improvements and Profile ramping for Lead In/Out moves.

- Setting separate feed rates for Entry and Exit linking moves.

- And much more.