Contact Details

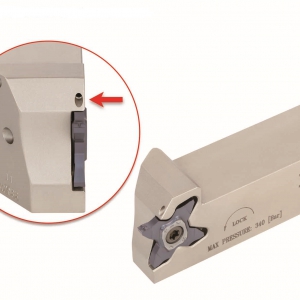

Tungaloy has expanded its DoMultiRec multifunctional milling/drilling tool line by adding three additional diameter options of modular cutting heads and two new inserts with nose radius variations.

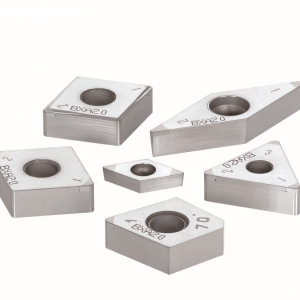

DoMultiRec multifunctional milling cutter with center cutting capability enables a single tool to perform multiple milling operations, including shouldering, pocketing, and drilling. A uniquely designed insert integrates a center and peripheral cutting edge on one side of the insert, and, since the insert is double sided, the same insert can be used either for the center or peripheral position for up to four indexings, front and back. This doubles the cost-per-edge economy when compared with conventional plunge milling cutters using single-sided inserts. Furthermore, the insert features -MM geometry that is developed specifically for the DoMultiRec inserts to ensure strong and sharp cutting edges during various milling and drilling operations.

The inserts are optimally arranged on the cutter so that they create a near-flat surface of the hole bottoms when drilling blind holes.

New modular cutting heads are available in 17 mm (.669″), 21 mm (.827″), and 26 mm (1.024″) diameters. When these cutting heads are coupled with the holders, respectively, with 16, 20, and 25 mm diameter shanks, they provide a clearance between the tool and the workpiece shoulder, allowing the tool to machine extremely close to the shoulder without the concern for tool collision.

Two new LXMU10T304PER-MM and LXMU120404PER-MM inserts have 0.4 mm (.016″) nose radii. They are especially effective when machining the shoulders requiring a corner radius of 0.5 mm (.020″) or smaller.

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- plunge milling

plunge milling

Highly productive method of metal removal in which an axial machining operation is performed in a single tool sequence. The tool makes a series of overlapping, drill-like plunges to remove part of a cylindrical plug of material one after another. Because of the increased rigidity of a Z-axis move, the tool can cover a large cross-section of material.

PRODUCTS

PRODUCTS