New Release of Edgecam Software

New Release of Edgecam Software

The new release of Edgecam, from Vero Software, contains 54 items of new or enhanced functionality that improve productivity for manufacturers by using a range of cutting technologies and machining strategies. They include significant changes to the Pre-Drill Approach Roughing cycle, creating features from wireframe entities, 3D milling cycles in mill-turn Rotary mode, 28 new technology databases in the Wire EDM module and Tombstone.

The new release of Edgecam, from Vero Software, contains 54 items of new or enhanced functionality that improve productivity for manufacturers by using a range of cutting technologies and machining strategies. They include significant changes to the Pre-Drill Approach Roughing cycle, creating features from wireframe entities, 3D milling cycles in mill-turn Rotary mode, 28 new technology databases in the Wire EDM module and Tombstone.

Edgecam Brand Manager John Buehler says that every user will benefit from at least one of the enhancements, the most significant of which is a complete transformation to the Tombstone Manger, thanks to 13 enhancements.

The new Add Tombstone function ensures users never overwrite their master tombstone assembly file (referred to as Seed file). The originating file is always protected, guaranteeing that vital information is never overwritten.

The number of components that can be inserted onto the Tombstone is now limitless, reflecting best industry practice. Once inserted, the toolpaths are not only automatically merged, but the enhanced Closest Next ordering further economizes the CAM toolpaths.

"Arguably the most significant individual enhancement is the ability to retrospectively edit the CAM toolpaths," he says. Using the new 'Edit' and 'Reload' functions, Edgecam will independently open the inserted file, allowing the user to perform unlimited edits to the CAM instructions. Once finished, the seed file is automatically updated with the new editions.

The way the Pre-Drill approach strategy is handled has been significantly improved within the Roughing cycle. "Rather than manually create drill-hole positions, which is sometimes time consuming, Edgecam 2018 R2 automatically creates the hole position and keeps the drilling toolpath associative to the Roughing cycle," Buehler says. "Simply by activating the command, users can deploy the multilevel and depth functions within a hole cycle to automatically locate the best entry position for the drill cycle."

The Rough Turn cycle includes several new lead parameters allowing the user to roll in and out of each cut with a tangential arc. A bidirectional toolpath can be created, allowing the cycle to be used in conjunction with Sandvik Coromant's CoroTurn Prime turning inserts. Significant time savings and reduced tool wear can be achieved when adopting these methods.

Also, the cycle's collision detection capability has been extended by automatically removing any potential crashes between the tool and the tailstock.

Edgecam Inspection module's evolution continues with 14 enhancements, including full postprocessor support with the Code Wizard.

Major items include the introduction of NC Gateway, which communicates with the machine tool, plus Best Fit calculation, which allows alignment of the workpiece. In addition to the new Inspect Rectangle feature, both the Options and Inspect Toolpath dialogs include new features. Users may now influence both the Work Datum and the Tool Offset and view the status from within the NC output and the Inspection Report.

Edgecam Designer's 2D Drawing Module creates views and sections of the 3D model in the Designer file. Features include dynamic view creation, shaded and wireframe views, fixed and variable sections, detailed views, and outbreaks. The 2D drawing and its associative dimensions can be updated when changes are made to the 3D model.

The many sketching and modelling enhancements throughout Edgecam Designer include the Active Sketch Plane, which allows wireframe to be created directly onto solid and surface models, without the need for workplanes.

Additionally, it is now possible to create the Projected Area of solid and surface models, and new analysis functionality calculates aspects such as area, volume, perimeter, and center of gravity.

Through improvements in the toolpath algorithm, Edgecam 2018 R2 provides a significant performance improvement with the Pick Solid Faces function. Time savings of over 50 percent can be achieved thanks to the manner in which the cycle gathers data for toolpath calculation.

"Users will also gain further benefits when using the Multi-Pass function, as the strategy is now supported with helical capability," Buehler says.

Buehler says it wasn't previously possible to create a feature from wireframe entities. "In certain situations, such as creating automation routines, that would have been desirable, so Edgecam 2018 R2 now unlocks the ability to deploy workflow strategies, where ordinarily a feature couldn't be created, by converting line and arc data into a solid Feature. Once machined, the new feature can be edited and the toolpath will remain associative."

Found in both the milling and turning environments, the Thread Mill cycle has been enhanced to allow closer toolpath control and greater flexibility. Five new parameters allow users to deploy "peck" and "multipass" toolpaths. This will especially help when machining hard materials or when a better surface finish is required.

Further new options found in the Lead tab deliver additional control with toolpath ordering.

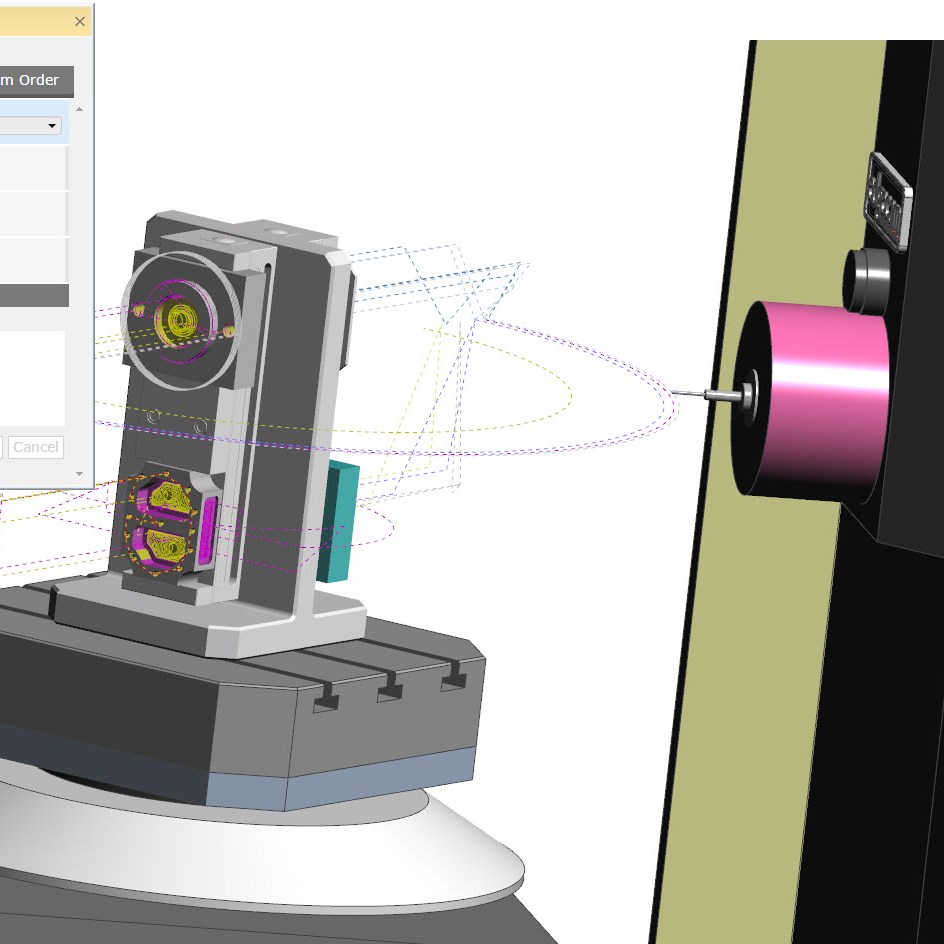

3D milling cycles in the mill-turn environment have now become available while working in Rotary mode. Previously, these cycles were restricted to Planar mode. "This enhancement offers greater flexibility in not only unlocking the seven milling cycles which were normally unavailable, but allows users to overcome machine-tool limit issues," Buehler says.

When being forced to use the same tool number, but for different tools, programmers in the turning environment can now use the Replace Active Tool function so that the simulator will only display a single tool in the turret during playback. Users can now also increase playback performance by using the new "simplify solid mill cutters" command. When using complicated solid-model cutters, the function will simplify the profile by converting it into a silhouette.

Buehler says, "When viewed individually, small enhancements don't appear to have a significant impact. However, when added together, their sum total has an important effect on the day-to-day operation of the software. And all the updates here were driven by customer requests/feedback."

A good example are the three enhancements found in the Preferences section of Edgecam 2018 R2. Users now have the choice to activate a toolkit by simply using the new Automatically Create Toolkit check-box. They can also use the new Job/Toolkit Update preferences settings when generating NC output. Additionally, the new "technology warning" check-box helps avoid misrepresenting tool feed and speed settings.

Manufacturers working with turning tools can now pre-state the CSS condition from the tool store. This avoids individually setting the status every time the tool is chosen.

In the case of Face Grooving tools, programmers can now add further detail to the description of the tool by adding Maximum/Minimum Diameter, which is particularly useful for Strategy Manager authors. An additional turning enhancement, Edgecam 2018 R2 allows any tool type to be deployed when executing the Thread Turning cycle.

Edgecam 2018 R2 introduces 28 new technology databases to the Wire EDM module, including the popular Agie, FANUC, Makino and Mitsubishi controllers.

During the machine simulation stage, the "start hole" (entry position for the wire) is created automatically, alleviating the need to manually create the hole in the stock.