PG1000 Optical Cutting Tool Inspection System

PG1000 Optical Cutting Tool Inspection System

The PG1000 optical cutting tool inspection system has been manufactured and sold through a division of Euro-Tech Corporation since 1993. Effective November 20, 2019, the PG1000 is manufactured, sold, and serviced throughnPG Inspection Technologies.

The PG1000 optical cutting tool inspection system has been manufactured and sold through a division of Euro-Tech Corporation since 1993. Effective November 20, 2019, the PG1000 is manufactured, sold, and serviced through

PG Inspection Technologies.

Because this new company is dedicated solely to the PG1000, we will be able to better support our existing and future customers. Our commitment to our customers and partners remains our highest priority.

In 1993, Euro-Tech designed and began to manufacture the PG1000 in the USA. The original PG1000 was a manual gauge which used a Swiss-made monocular microscope and digital readout. This system was capable of measuring step lengths, diameters, relief and clearance angles, margin, and land widths. With time, more customers voiced that they would like a cutting tool inspection system that used a video camera/microscope in place of the monocular microscope.

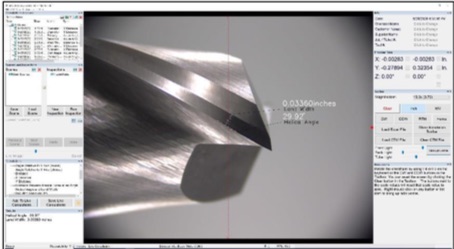

In 1996, Euro-Tech was the first to introduce a cutting tool inspection system using a 0.5 MB video camera, frame grabber, and Windows 95 PC with the first generation of our proprietary software.

As the digital age evolved, so did the PG1000. Today's PG1000 cutting tool inspection system uses a 5MB camera, 4K monitor, and 6X and 12X zoom modules. Our evolving REACTION software allows our PG1000 cutting-edge inspection systems to be capable of tool geometry measurements to the micron level.