Contact Details

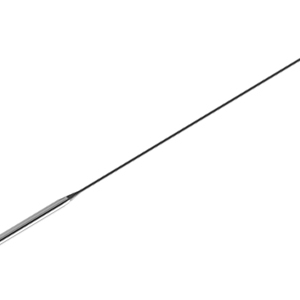

Building on the success of the Phoenix high performance drill from Sphinx, BIG Kaiser has introduced the new Power-Phoenix extra long high performance drill series. The drills are designed for optimal performance in deep hole applications in steel, stainless steel, cast iron, aluminum and titanium.

Power-Phoenix drills feature a 137-degree point angle and four-margin geometry (above a 2.0mm diameter) for stability, ensuring a straight hole even in deep drilling applications. A unique point grind ensures consistent chip formation, while specially designed polished flutes allow for rapid chip evacuation. Through-coolant capability is standard, and the Power-Phoenix was designed to perform with even low coolant pressure down to 290 PSI (20 bar).

"These features, plus a state-of-the-art, wear resistant Helica coating, make the Power-Phoenix the ideal high performance drill of deep hole applications," says Mike Bojanowski, BIG Kaiser assistant product manager for the Sphinx drill line.

The diameter range available is 1.0mm-12.7mm for the 16xD version, and 2.0mm-10.0mm for the rest of the drill series: 20xD, 25xD, 30xD.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- point angle

point angle

Included angle at the point of a twist drill or similar tool; for general-purpose tools, the point angle is typically 118°.

PRODUCTS

PRODUCTS