Production Module Upgrade

Production Module Upgrade

Third Wave Systems introduced its newest machining modeling capabilities: part distortion and tool deflection.

Third Wave Systems introduced its newest machining modeling capabilities: part distortion and tool deflection. The product has been under development for more than five years, and will be sold as an upgrade to the company's NC program optimization software, Production Module, beginning in November of 2011.

Its most well-known product, AdvantEdge FEM, is finite element analysis software developed specifically to model material behavior during metal cutting processes such as drilling, milling, grooving, and turning. The same material models used for this finite element analysis are also incorporated into Production Module, Third Wave's CAE software that provides a more comprehensive, transformative solution for toolpath analysis and optimization.

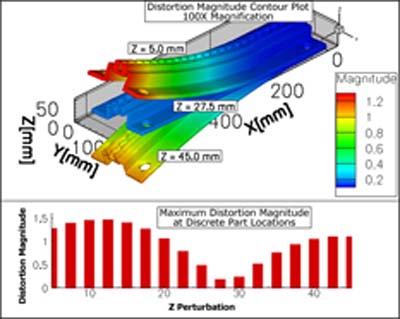

With the release of its predictive part distortion and tool deflection capabilities, Third Wave Production Module users will be able to analyze legacy and new machining strategies with consideration not only for tool performance and production times, but also for the dimensional accuracy of final parts. With the ability to simulate, analyze, and visualize multiple part geometries and their impact on distortion, Production Module may also be used earlier in the product design cycle by engineers looking to design products for future manufacturability.

Indeed, the new upgrade to Production Module will offer a drastic departure from the current practices for limiting part distortion. Instead of making machining improvements based on countless trial-and-error tests, or sending parts out for secondary operations after machining, both of which can be costly and time-consuming, manufacturers will be empowered to proactively identify machining parameters that deliver optimal part quality in minutes, with only a few clicks of a mouse. The technology presents an immediate business case for companies looking to innovate with minimal risk to their bottom lines.

Consistent with its current software packages, Third Wave Systems engineers have developed this new modeling upgrade with usability in mind. The software reads 5-axis APT and G-codes, permits importing of STEP and STL files, incorporates a database of workpiece bulk stresses, and automatically generates a thin-wall mesh. Factors such as cutting force distribution along the flute length, instantaneous cutting forces, and changes in cross-sectional moments of inertia along a tapered tool are also modeled automatically, further simplifying process setup.