Contact Details

Emuge Corp. has introduced its patented Punch Tap Line in North America. The Emuge Punch Tap is for helical thread forming in cast and wrought aluminum alloys and similar lightweight materials. Emuge Punch Taps provide a new, shortened tool path process for producing internal threads in under half a second, resulting in significantly less energy consumption during the machining process and a reduction in threading time by 75 percent compared to cold forming and conventional tapping.

"Emuge originally partnered with Audi AG in Europe to develop the unique Punch Tap design and technology," said Bob Hellinger, president of Emuge Corp. "This revolutionary tool is exceptionally productive and we are thrilled to now offer the technology to our customers in North America."

Due to its extremely fast threading capabilities, high-volume applications such as in the automotive industry are ideal for the Punch Tap. Emuge Punch Taps provide an excellent thread production solution for manufacturers who produce high-volume parts and need to reduce cycle times.

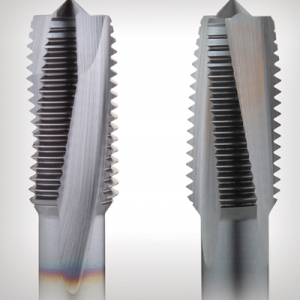

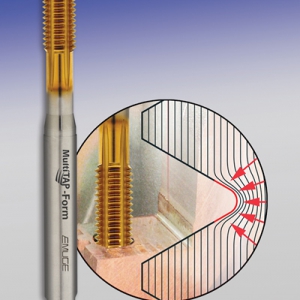

Punch Taps are made from a special HSSE-PM alloy optimized for toughness and long wear, and have an exclusive design offering several benefits such as unique teeth geometry that produces threads in a single step. The Punch Tap features two rows of flutes off-set 180° from each other and extending in a helical curve all the way down to the usable application depth. This design enables an extremely efficient toolpath that is approximately 15 times shorter for a M6 thread with a depth of 15mm compared to traditional cutting or cold-forming taps. The shortened tool path facilitates a threading process which is completed in less than half a second.

Prior to the threading operation, the tool quickly punches into a predrilled hole and the first tooth of each flute produces a helical groove which assists in guiding the tap to the application depth. Once the depth is reached, threading commences by cold forming with a synchronous movement of feed and rotation. The thread is produced with a half left-turn in the pitch, and each tooth of the Emuge Punch Tap produces half a thread (approximately 180°). After the threads have been formed, the Punch Tap is retracted in a helical movement from the hole via the grooves. The finished cold-formed thread is interrupted by two helical grooves offset by 180°.

Thread strength is maintained and is comparable to conventionally machined threads from a depth of thread of 2xD. The Emuge Punch Taps, engineered and optimized for coatings and dimensions according to application requirements, are available by special order. Punch Taps are used for blind and through-holes, and can be used for the production of metric threads from M3 thru M10 with thread depths up to 2xD (inch sizes are also available from #8 thru 5/16). Emuge Punch Taps have internal coolant supply capability using emulsion or minimum quantity lubrication (MQL). The taps are used on CNC machines programmed with a specialized punch tap cycle, available from machine tool and control unit manufacturers. Machine parameters, such as acceleration, will require adjustment for some applications.

For superior tool holding, an inclined clamping flat on the Punch Tap fits precisely with an Emuge PT-Synchro Punch Tap Holder. Force-locked rigid clamping via a cylindrical ER collet offers a high torque, highly secure solution with excellent run-out accuracy. To gage the diameter of the helical thread, an Emuge Thread Plug Gage offers go/ no-go inspection according to DIN ISO 1502.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum alloys

aluminum alloys

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- emulsion

emulsion

Suspension of one liquid in another, such as oil in water.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.

PRODUCTS

PRODUCTS