Contact Details

With an advanced solution that enables manufacturing companies to take steps towards digital machining and Industry 4.0, Sandvik Coromant has introduced connectivity capability to its series of Silent Tools toolholders. The innovation is offered as part of the company’s CoroPlus suite of connected solutions for machine shops keen to embrace the rapidly advancing trend of industry digitization.

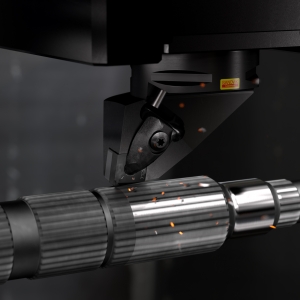

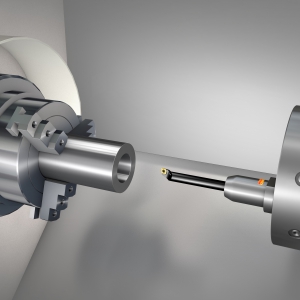

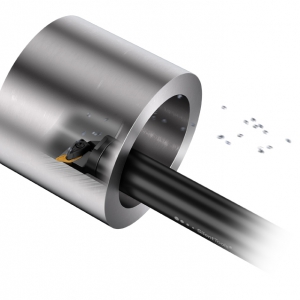

Among a number of enhancements, the latest Silent Tools technology for internal turning at long overhangs now feature embedded connectivity within the adaptor. Named Silent Tools Plus, this solution enables data from the machining process to be collected and sent to a dashboard, giving the operator a valuable insight into what is happening inside slender tubular components. For instance, it will be possible to detect if there is too much vibration or if the surface quality is at risk of being compromised. Furthermore, operators will be able to reduce the time that the machine runs without the tool in cut.

“The combination of CoroPlus connectivity and Silent Tools damping technology makes this a solution that shows the technical heights we can expect from the machining solutions of the future,” says Åke Axner, product manager Silent Tools Turning Adaptors at Sandvik Coromant. “Silent Tools Plus turning adaptors with embedded connectivity support our overall CoroPlus strategy, which enables customers to work more efficiently.”

By way of example, the Silent Tools Plus vibration indicator is able to detect issues with machining at an early stage, helping to prevent vibration-associated issues such as noise, poor surface quality and accelerated tool wear. Furthermore, center height setting functionality displays the level of the cutting edge, so that it can be quickly and easily set according to requirements. The result is better machining performance and longer tool life.

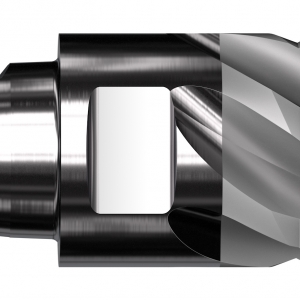

The range of Silent Tools from Sandvik Coromant is designed to minimize vibration through a pre-tuned dampener inside the tool body that consists of a heavy mass supported by rubber spring elements. The benefits of this design are multiple-faceted, allowing machine shops to increase metal-removal rates, improve surface finish, secure the process or reduce production costs.

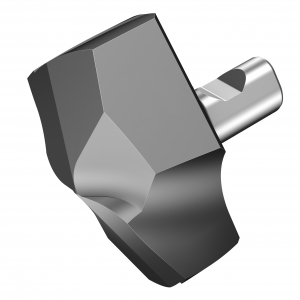

The Silent Tools Plus turning adaptor also includes a new Wedge Lock quick-change interface between the adaptor and cutting head. The fast and accurate cutting head changes this facilitates will appeal to manufacturers in a variety of industries, including aerospace, for machining components such as landing gear components, and in oil and gas, where the machining of long tubular parts is commonplace.

Related Glossary Terms

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS