Contact Details

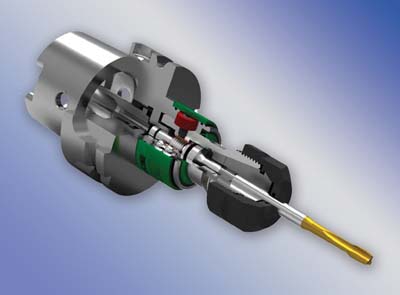

Emuge Corp. has introduced a series of tool holders with variable exchangeable transfer elements and length adjustment screws. Designed for machines with synchronous spindles, the new Softsynchro HD and MQL Modular System makes it possible for the same tool holder body to be used for minimal quantity lubricant (MQL) or HSK coolant applications.

The modular tool holder can also be supplied with a spring-loaded tube, the preferred method in MQL applications. The same style adjusting screw can also be added to the HD unit in the high-pressure SSY holders. Adjustable coolant tubes are added based on the tap size and style. Users can also order the HSK tube based on a one-channel or two-channel system or HSK-C connection. SSY modular tools can also be custom-built from standard components, depending on the tap size and application.

The modular system also employs a new Heli coil mechanism designed to reduce the force that occurs when tightening the collet nut. When tightening the collet nut with the tap fixed against the adjusting screw, there typically is movement which can damage the tap or adjusting screw. The axial movement of the collet can be (0.08 to 0.3), with forces of (800N to 5000N). The heli coil mechanism compensates for this axial movement, preventing unwanted displacement and potential damage to the tap or MQL adjusting screw. The new modular bodies are available in sizes KSN1 ER20 and KSN3 ER32.

Related Glossary Terms

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

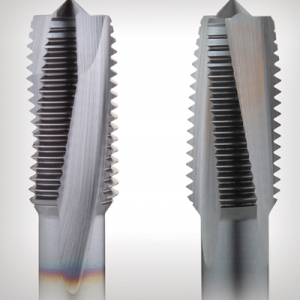

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

PRODUCTS

PRODUCTS