Contact Details

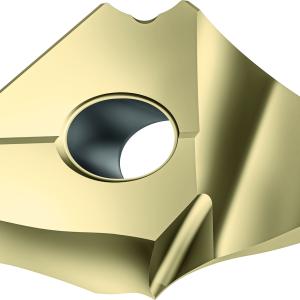

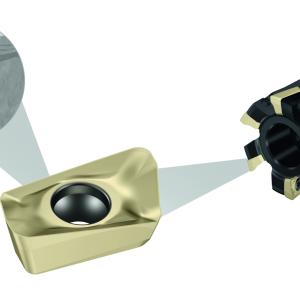

Walter has introduced a pair of versatile, high performance and cost-effective taps: the Walter Prototyp TC115, designed for blind-hole threads, and the TC216 for through-hole threads. The taps are able to tackle an array of materials ranging from steel to aluminium (ISO material groups P, M, K, N), save cost by reducing the number of taps needed, and also reduces the investment involved in tap inventory.

The two new taps combine superior performance characteristics with their cost-saving versatility. The TC115 blind-hole tap has a 45° helix angle for thread depth of 3xD, and a C form chamfer. The TC216 through-hole tap features a spiral point for forward chip evacuation and thread depth of 3.5 times diameter. Both have HSS-E bodies and are available with either TiN or vaporized coating. The vaporized variant is a particularly good choice for tough ISO M materials because it increases process reliability, while longer tool life and higher cutting speeds are just some of the benefits of the TiN coating.

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- helix angle

helix angle

Angle that the tool’s leading edge makes with the plane of its centerline.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

PRODUCTS

PRODUCTS