Contact Details

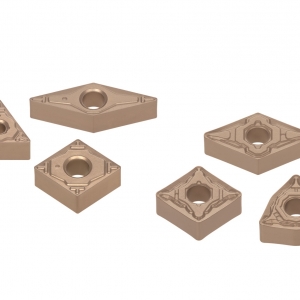

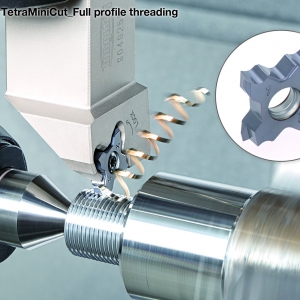

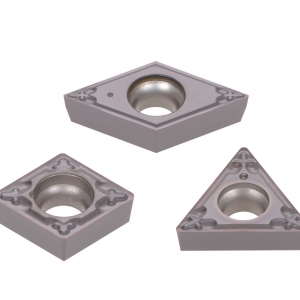

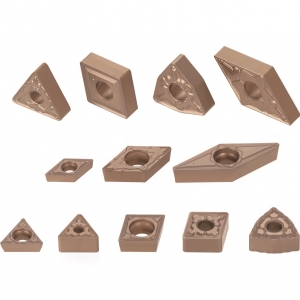

Tungaloy is enhancing TetraMini-Cut, one of the best of its grooving tool family, by adding a substantial number of new items to its TCG18 insert lines.

Compact and offering economical, four-edged geometry, TetraMini-Cut incorporates a rigid insert clamping system that ensures high indexability and accuracy, extending insert life to the maximum level.

This major addition to the TCG18 insert lineup will make TetraMini-Cut an even more flexible series. Wider spectrums of workpiece profiles, materials, and machine setups will now be covered by this expansion, ranging from small and miniature parts in Swiss-type machines to general-lathe grooving and threading applications.

The TCG18 insert is available in AH7025, a dedicated grooving grade optimized for extreme resistance to chipping and plastic deformationto deliver secure performance and high metal-removal rates in the most demanding operations.

Related Glossary Terms

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

PRODUCTS

PRODUCTS