Contact Details

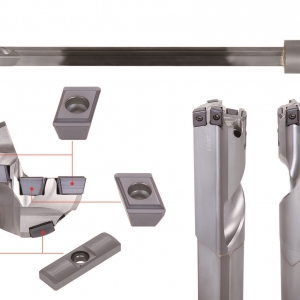

Tungaloy has announced the introduction of two brand new TungCut CBN-tipped inserts: STH300-SR BXA10 and STH500-SR BXA10 for efficient finish turning of hardened steel parts.

CBN inserts used for the finish O.D. turning process of hardened steel parts are generally offered in standard ISO shapes. Since 2.4 mm (.094″) nose radius is the largest available of these standard inserts, shops must use a significantly reduced feed rate to achieve a high-quality surface finish, which limits cycle time improvement. Likewise, when machining the shaft surface located in between two close shoulders of larger diameters using standard ISO CBN inserts, shops customarily use two different turning tools just to avoid interferences with the workpiece shoulders.

TungCut CBN-tipped STH inserts provide the solution to these challenges with a completely new turning concept. In the shape of TungCut grooving insert, the new STH inserts perform finish-turning by feeding the insert sideways on the worked surface. Its CBN cutting edge features a unique wiper geometry: the frontal edge features an arc wiper of large radius. This generates superior surface finish in straight-line turning applications, while also allowing increased feed rates of up to 1.5 mm (.060″) per revolution with up to 0.1 mm (.004″) d.o.c. The wiper on the side edges is also designed to provide improved surface quality during finish-facing operations. In addition, Tungaloy’s unique WavyJoint technology creates a strong joint of the CBN tip and carbide insert base at larger contact areas. This not only enhances the brazing strength between the two parts but also promotes the dissipation of cutting heat built up during aggressive high feed machining, thus preventing the CBN tip from debrazing and insert failure.

STH inserts are interchangeable with other TungCut grooving inserts and can be used with the existing toolholders with a seat size of 3 or 5. Facing and I.D. turning is also possible with select toolholders.

Related Glossary Terms

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS