Contact Details

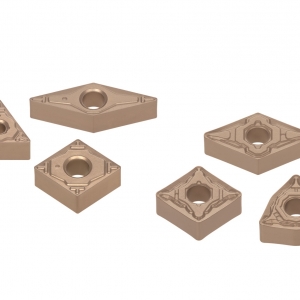

Tungaloy has added a total of 42 carbide shanks to its TungFlex modular milling tool system that opens up many flexible combinations of tool assemblies.

TungFlex modular milling tool system provides the ability to build an optimized and tailored assembly for a specific application using standard cutter heads, shanks, and holders. TungFlex now offers a carbide shank line in addition to the existing steel shank line.

Since carbide shanks provide lower deflection than steel shanks, they enable aggressive machining with increased cutting parameters. This amounts to reduced machining time and increased productivity. Also, the new shanks provide excellent vibration resistance, enabling extremely productive machining with long overhang setup. Furthermore, their coolant-through capability directs cutting fluid precisely to the cutting point, providing optimal milling performance in pocket and cavity machining, in which effective chip evacuation is critical.

Related Glossary Terms

- cutting fluid

cutting fluid

Liquid used to improve workpiece machinability, enhance tool life, flush out chips and machining debris, and cool the workpiece and tool. Three basic types are: straight oils; soluble oils, which emulsify in water; and synthetic fluids, which are water-based chemical solutions having no oil. See coolant; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS