Contact Details

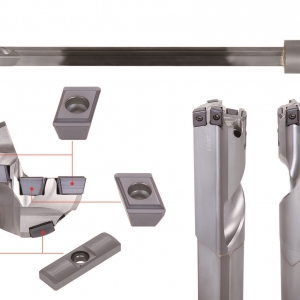

Tungaloy is adding new insert radius sizes to its TungUniversalSlot and TecTangentialSlot slot milling cutter series.

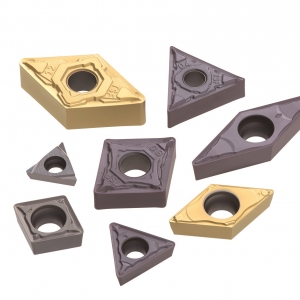

Both TungUniversalSlot and TecTangentialSlot are indexable slot milling cutters with unique insert features. Traditional slot milling cutters require two different shapes of inserts in pairs, using one shape for the right corner and the other for the left, in order to complete the slot profile. Both TungUniversalSlot and TecTangentialSlot incorporate a double-sided insert, allowing one side to be used for the right hand and the other for the left hand. TungUniversalSlot has six cutting edges per insert and TecTangentialSlot 4 cutting edges per insert. These insert features contribute to significant improvement of cost-effectiveness with less tool investment and inventory management.

In addition, the insert cutting edge is designed to generate light cutting force and stable cutting even under heavy chip load. The inserts are available in grade AH3135 boasting high fracture toughness and AH120 with wear resistance for long tool life in various materials.

Due to popular demand, the new standard radii sizes include 0.4 mm, 1.0 mm, 2.0 mm, 3.0 mm, 4.0 mm and 5.0 mm.

At a Glance

New inserts are available in 0.4 mm, 1.0 mm, 2.0 mm, 3.0 mm, 4.0 mm, and 5.0 mm radii sizes

High density and excellent chip evacuation provide increased productivity for various slot milling applications

Cost-effective double-sided inserts with multiple cutting edges, with one side for the right hand and the other for the left hand

Unique cutting edge geometry with integrated wiper flat for fine surface finishing

Available in AH3135 for high fracture toughness and AH120 for wear resistance

Total of 37 inserts to be introduced

Related Glossary Terms

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- fracture toughness

fracture toughness

Critical value (KIC) of stress intensity. A material property.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS